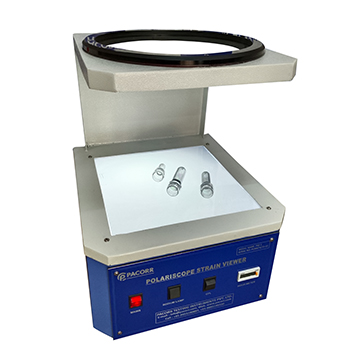

The Bottle Cap Torque Tester - Computerized is a vital tool for measuring the force needed to open or close bottle caps, making it an essential asset for the PET/Preform industry. This device ensures that caps strike the perfect balance between secure sealing and user convenience. It features a motor-driven mechanism that applies controlled torque to caps, with sensors delivering precise readings displayed on a digital interface. Supporting multiple measurement units and accommodating bottle caps of various sizes, it guarantees an accuracy of 0.5% FSD. Advanced features like peak hold, bidirectional torque measurement, and PC connectivity make it indispensable for quality control processes. With its robust design and user-friendly operation, this torque tester is a reliable solution for maintaining high packaging standards.

- Shipping Area: All over the world

- Model: PCTT-C

The Bottle Cap Torque Tester - Computerized is a specialized instrument designed for quality control in industries that rely on secure and functional packaging. This device measures the torque required to open or close a bottle cap, ensuring optimal sealing while maintaining user convenience. Its design includes a motorized torque application mechanism and precision sensors that provide accurate measurements. Results are displayed digitally and can be analyzed further via PC connectivity, making it a versatile tool for modern industrial needs.

The bottle cap torque tester supports various units of measurement, such as N-m, Lbs-Inch, and Kg-Cm, and is compatible with bottle caps ranging from 15 mm to 175 mm in diameter. This versatility allows it to cater to a wide array of industries, including pharmaceuticals, beverages, and cosmetics. Key features such as peak hold, tare function, and bidirectional torque measurement enhance its usability. Additionally, the RS232 communication port enables seamless data transfer for reporting purposes. Built to last, the tester ensures reliable performance even in demanding industrial environments.

Features and Benefits of the Bottle Cap Torque Tester

Benefits

- Enhanced Quality Control: Ensures bottle caps are securely sealed while being easy to open.

- Precise Measurements: Delivers high accuracy for reliable results.

- Versatility: Supports various cap sizes and measurement units for broader applications.

- Data Tracking: Provides detailed reporting for quality assurance and compliance.

- Durable Build: Designed to withstand industrial use.

Features

- Peak Hold Facility: Records the maximum torque applied during testing.

- Bidirectional Torque Measurement: Measures both opening and closing torque.

- Multi-Unit Support: Displays readings in N-m, Lbs-Inch, and Kg-Cm.

- Tare Function: Enables accurate zeroing of readings.

- Digital Display & PC Connectivity: Features an LCD screen and RS232 port for efficient data management.

FAQ's

Q1. How does the bottle cap torque tester handle different cap sizes?

A. The Computerized Bottle Cap Torque Tester is designed to accommodate a broad range of cap sizes, making it versatile for various industries. It can measure torque for caps with diameters ranging from 15 mm to 175 mm. This range ensures compatibility with diverse packaging formats, such as small pharmaceutical vials, standard beverage bottles, and even larger jars used in food or industrial applications. By adjusting the settings, operators can seamlessly switch between different cap sizes, allowing for efficient testing across various product lines without the need for additional equipment.

Q2. What industries benefit from the bottle cap torque tester?

A. The bottle cap torque tester is indispensable in industries where packaging plays a critical role in product safety, quality, and consumer satisfaction. In the PET/Preform industry, the tester ensures that caps are sealed properly to preserve the product's integrity. Pharmaceutical companies rely on the tester to maintain tamper-evident packaging standards while ensuring ease of opening for patients. The food and beverage industry uses it to confirm that caps prevent leaks and contamination, while cosmetic manufacturers ensure their packaging meets aesthetic and functional standards. This device's versatility makes it a valuable asset in any sector that prioritizes precision in packaging.

Q3. Can the bottle cap torque tester generate detailed reports?

A. Yes, the bottle cap torque tester is equipped with advanced reporting capabilities, making it an essential tool for quality assurance. After each test, the device generates comprehensive reports that include critical data such as peak torque values, operator IDs, sample IDs, and timestamps. These reports are stored digitally and can be transferred to a connected computer via the RS232 communication port. This functionality simplifies record-keeping, enables detailed analyses, and ensures compliance with industry standards. Businesses can use these reports to track trends, identify inconsistencies, and improve their production processes over time.

Q4. What is the accuracy level of the bottle cap torque tester?

A. The bottle cap torque tester delivers exceptional precision, boasting an accuracy level of ±0.5% Full Scale Deflection (FSD). This high level of accuracy ensures that measurements are consistent and reliable, making it suitable for critical quality control operations. Even small deviations in torque can lead to product spoilage, leaks, or consumer dissatisfaction, making precision vital. The device’s advanced sensors and calibration mechanisms ensure that every measurement reflects the true torque required, whether for opening or closing a bottle cap. This reliability helps manufacturers maintain consistent product quality and meet regulatory standards.

Q5. Is the bottle cap torque tester easy to interface with a PC?

A. Yes, the bottle cap torque tester is designed for seamless integration with most modern computers. It includes an RS232 communication port, which facilitates a reliable connection between the device and a PC. Through this interface, operators can transfer test data directly to their computers for further analysis or long-term storage. The device often comes with compatible software or drivers, simplifying installation and use. However, users must provide their own computer or laptop for interfacing. The ability to connect to a PC also enhances the device's reporting functionality, enabling users to compile detailed records, generate charts, and improve quality control processes.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.