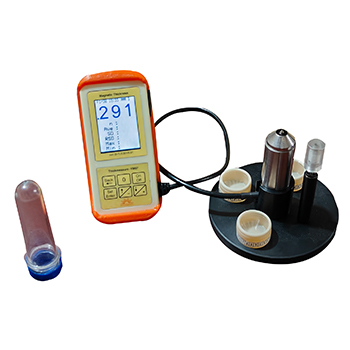

Bottle Wall thickness gauge is one of best instruments that can be used for testing of thickness of packaging containers such as PET and plastic bottles. The Wall Thickness Gauge can be used for testing the thickness of the containers that cannot be measured through conventional methods. In the PET industry, the quality of PET containers and bottles is very important as the quality of the bottles is wholly responsible for the quality and safety of the products.

- Shipping Area: All over the world

- Model: PCWTG-D

The Bottle Wall Thickness Gauge, especially the digital version offered by Pacorr, represents a leap in precision measurement technology. Designed for a variety of industries, including beverages, pharmaceuticals, and cosmetics, these gauges ensure bottles possess the requisite wall thickness for optimum quality and performance.

Understanding the Importance of Bottle Wall Thickness

A bottle's wall thickness is directly linked to its structural integrity and overall quality. Variations in thickness can cause issues such as product leakage, compromised strength, and poor aesthetic appeal. Precise measurement tools like Pacorr's Bottle Wall Thickness Gauge ensure consistent wall thickness, thereby maintaining the structural integrity and quality of the product.

Material Efficiency and Environmental Sustainability

Accurate control over wall thickness allows manufacturers to optimize material use, reduce production costs, and minimize environmental impact. By ensuring material is not wasted on excessively thick bottle walls, companies can achieve greater sustainability in their manufacturing processes.

Regulatory Compliance

In industries subject to strict regulations regarding packaging quality, consistent wall thickness is non-negotiable. The Bottle Wall Thickness Gauge helps manufacturers adhere to these standards, avoiding potential legal issues and costly recalls.

Advantages of Pacorr's Bottle Wall Thickness Gauge

Pacorr's gauges are equipped with state-of-the-art technology that provides accurate, reliable measurements. Features include a digital display, user-friendly interface, and non-destructive testing, ensuring that every bottle can be measured without material waste.

Versatility and Real-Time Monitoring

The versatility of Pacorr's gauges allows for their use across various bottle materials. Real-time monitoring capabilities enable manufacturers to detect any deviations in wall thickness immediately, facilitating quick corrective actions to maintain quality standards.

Ensuring Consistency and Cost-Effectiveness

By utilizing these advanced gauges, manufacturers can significantly reduce the occurrence of defects, streamline production processes, and cut costs. Consistency in wall thickness leads to fewer defects, less waste, and improved product quality—factors that are directly linked to better sales and market competitiveness.

Boosting Brand Trust and Reputation

Investing in precise measurement tools like the Bottle Wall Thickness Gauge from Pacorr can help businesses deliver consistent, high-quality products. This not only enhances brand reputation but also builds trust among customers and retailers alike, contributing to improved sales figures.

The Bottle Wall Thickness Gauge is a vital tool for any manufacturer seeking to ensure the quality and consistency of their bottle products. Pacorr's offering, with its advanced technology, precision, and versatility, stands out as a top choice for industries ranging from beverage production to pharmaceuticals. By integrating these gauges into their quality control processes, manufacturers can achieve material efficiency, comply with regulatory standards, and enhance their brand reputation, ultimately leading to better business outcomes.

Bottle thickness gauge are essential tools for ensuring the quality and performance of bottles, especially in industries where consistent thickness is critical, such as in the production of glass bottles or plastic containers for beverages, pharmaceuticals, or chemicals.

Bottle Wall Thickness Gauge Digital is a highly precise testing instrument that is used mostly to measure and test the wall thickness of the products and surfaces which are not possible to measure through the conventional measuring methods such as measuring tapes or Vernier Callipers. In most of the industries, where PET bottles are used for packaging of the products, the quality of the bottles is a very important aspect that ensures the safety of the products inside them. This is why the wall thickness of the bottles needs to be measured to ensure the best strength and quality of the bottles.

| Aspect | Detail |

| Importance | Essential for quality control, ensuring structural integrity and regulatory compliance. |

| Technology | Utilizes cutting-edge technology for precise, non-destructive measurements. |

| Industries Served | Beverage, pharmaceutical, cosmetics, and more. |

| Benefits | Improved product quality, material efficiency, cost savings, and environmental sustainability. |

| Product Features | High precision, versatility across bottle materials, real-time monitoring. |

| Manufacturer | Pacorr, a leader in quality testing instruments. |

FAQ's

Q1. How does a Bottle Wall Thickness Gauge work?

A. A Bottle Wall Thickness Gauge operates based on principles such as electromagnetism for non-ferrous materials. It uses a guiding metallic ball or electromagnetic waves to measure the thickness of a bottle's wall, providing accurate measurements regardless of the bottle's shape.

Q2. What materials can be measured with a Bottle Wall Thickness Gauge?

A. These gauges are versatile and can measure the thickness of various materials, including plastics and glass. This makes them suitable for a wide range of industries, from beverages and pharmaceuticals to cosmetics.

Q3. Is the Bottle Wall Thickness Gauge suitable for regulatory compliance?

A. Yes, using a Bottle Wall Thickness Gauge can help ensure that bottles meet industry-specific regulatory standards for thickness. This is crucial for manufacturers who need to adhere to stringent quality control and regulatory compliance standards.

Q4. Can the Bottle Wall Thickness Gauge be connected to a computer for data analysis?

A. Many models of the Bottle Wall Thickness Gauge offer computer connectivity options, such as USB or RS232 ports. This feature allows for easy download of test data to a computer for further analysis, enhancing the efficiency of quality control processes.

Q5. How does using a Bottle Wall Thickness Gauge benefit manufacturers?

A. Utilizing a Bottle Wall Thickness Gauge allows manufacturers to maintain consistent quality, optimize material usage, and reduce waste, leading to cost savings and environmental benefits. It also ensures that products meet regulatory standards, reducing the risk of recalls and enhancing brand reputation.

Q6. What is the price of a Bottle Wall Thickness Gauge?

A. The price of a Bottle Wall Thickness Gauge from Pacorr typically ranges between INR 90,000 to INR 5,20,000, depending on the specific model and its features.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.