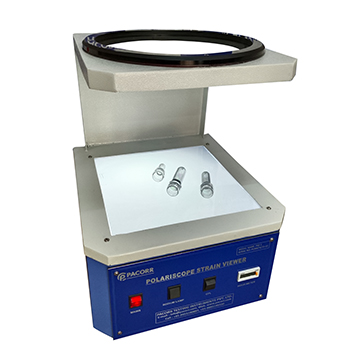

A Vision Measuring System is a high-precision instrument used to measure small parts with exceptional accuracy. It employs high-resolution cameras and optical imaging technology to capture detailed images of components, which are then analyzed using integrated software. This system is vital for industries like aerospace, automotive, and electronics, where precise measurements are crucial for quality control and ensuring the proper fit and function of components. It helps reduce human error, enhances efficiency, and improves overall product quality.

- Shipping Area: All over the world

- Model: PC-SVI-IMG-3D

Pacorr's Vision Measuring System is engineered to cater to industries requiring ultra-precise measurements of small components where traditional measuring tools fall short. The system's reliance on optical imaging and interception principles for measurements sets a new standard in precision and accuracy, ensuring the highest quality of final products.

Understanding Vision Measuring Systems

Vision Measuring Systems use sophisticated optical and digital technologies to perform precise measurements. The heart of the system is a high-resolution camera combined with specialized software to analyze and measure parts based on captured images. These systems are particularly beneficial for components too small or complex for conventional measurement methods.

Why Pacorr's Vision Measuring System?

Pacorr's Model PC-SVI-IMG-3D is a standout with its blend of features designed for ease of use and exceptional accuracy:

- High-Resolution Imaging: Ensures detailed analysis of subjects for accurate measurement.

- Advanced Illumination: Utilizes fiber optic light and adjustable LED for optimal visibility and clarity.

- Versatile Measurement Capabilities: Capable of measuring a wide array of geometric shapes and sizes with precision.

- Enhanced Accuracy: Offers a measuring range of 150 x 100 x 100 mm with an accuracy (X/Y) of (3 + L/200) µm, ensuring high reliability.

Application Spectrum

The versatility of the Vision Measuring System makes it invaluable across various sectors, especially those dealing with micro-components, such as electronics, automotive, and precision engineering. Its ability to accurately measure linear and geometrical shapes, including ellipses, circles, and triangles, underlines its importance in quality control processes.

Pacorr's Vision Measuring System represents a leap forward in measurement technology, providing industries with a tool that guarantees precision, accuracy, and reliability. The integration of advanced optical imaging, digital analysis, and user-friendly features makes it an indispensable asset for quality assurance in manufacturing processes involving small and intricate parts.

Pacorr is one of the most magnanimous Vision Measuring System manufacturers and suppliers offering most accurate and precise measuring systems to the industries those need it. In many industries, there are very tiny and minute parts involved in making the final products. Now the measurement of these parts is also a great challenge as they are so little that they cannot be measured through the conventional methods such as tapes, callipers, or micrometres. But taking accurate measurements is also essential for better quality assurance of the final products as well. The reason for this is that these instruments are not able to reach the positions where the measurements are to be taken. Additionally, there is always room for human error and hence they cannot be used for such measurements. This calls for a requirement of a system that could reach such places and take measurements without leaving a chance for any error.

The vision measuring system offered by Pacorr is one of the most precise and ideal testing instrument that can be used for taking measurements where there is a need for a very high level of accuracy and the tolerances are very tight. With the help of this instrument, the manufacturers can rest assured that the measurements they have are of best accuracy and ensure best quality of the products.

The Vision measuring system is a device that uses the principles of optical imaging and interception to take measurement from the object. The instrument measures the coordinates and then calculates the linear as well as the geometrical shapes of the parts. The instrument can be used for measurement of a variety of shapes and sizes such as ellipses, linear measurements, circular measurements, triangular measurements and so forth. The instrument uses a diffused Led or halogen light sources. The illumination surface is made from fibre optics and adjustable LEC for better clarity. High resolution camera used with the instrument is very helpful in taking clear images for better analysis. The instrument is incorporated with computer software that helps in organization of the work flow and ensure the best measurement, recording and analysis of the subject.

| Aspect | Detail |

| Product Focus | Vision Measuring System (Model: PC-SVI-IMG-3D) |

| Applications | Used for accurate measurements of small and complex parts in industries |

| Key Features | High-resolution cameras, fiber optic light, adjustable LED illumination, manual operation mode, high magnification options |

| Benefits | Precision, accuracy, reduced human error, versatility in measuring various shapes and sizes |

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.