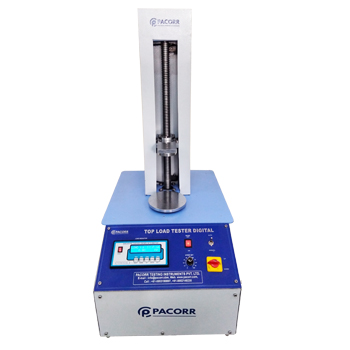

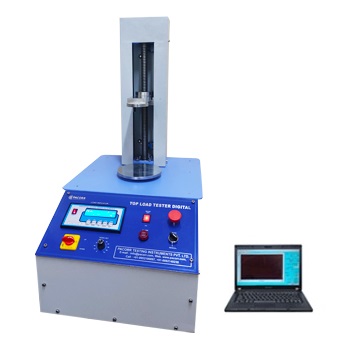

A top load tester is an instrument used to evaluate the load-bearing capacity of containers, primarily plastic and cardboard bottles and cans. It measures the amount of force required to crush a container or cause it to deform, which is crucial for assessing the structural integrity and durability of packaging materials. The tester is widely used in the packaging industry to ensure that containers can withstand the forces they encounter during shipping, handling, and storage, thereby preventing damage and preserving product quality. Bottle Top Load Tester - Ultra is used to measure the buckling strength of PET bottles or containers. The equipment can recreate the real-life compressive load a PET bottle can experience during storage or in transportation. Bottle Top Load Tester helps the user to evaluate the capacity of a bottle specimen against vertical compressive load.

- Shipping Area: All over the world

- Model: PCTLSC-1

The Bottle Top Load Tester, notably the Ultra model by Pacorr, is an essential instrument for measuring the top-load strength or resistance of bottles, jars, and containers made of plastic, glass, or metal. This guide delves into the significance, applications, features, and benefits of utilizing a Bottle Top Load Tester in various industries.

What is Bottle Top Load Testing?

Bottle Top Load Testing is a quality control measure that evaluates the maximum force a bottle cap or closure can withstand before it deforms or fails. It simulates real-world pressures experienced during storage, transportation, or use, ensuring that bottle caps or closures meet required strength and durability standards.

Importance of Bottle Top Load Testing

This testing is crucial for maintaining product quality, ensuring safety, and complying with industry regulations such as those set by the ISO, EUROPEN, and the FDA. It aids in optimizing packaging design, identifying weak points, and guiding improvements in materials and manufacturing processes.

The Pacorr Advantage

The Ultra model by Pacorr distinguishes itself through precision, versatility, and user-friendliness. It offers:

- Precise Measurements: Utilizes advanced technology for accurate buckling strength assessments.

- Versatility: Suitable for a wide range of bottle types and materials, enhancing its applicability across industries.

- User-Friendly Interface: Simplifies test procedures, allowing for efficient operation without extensive training.

- Automation and Efficiency: Features automated loading/unloading and rapid data analysis, streamlining the quality control process.

- Compliance with Standards: Meets international testing standards, ensuring global acceptance of test results.

Applications Across Industries

This tester finds extensive use in the food, beverage, pharmaceutical, cosmetic, and chemical industries. It plays a critical role in ensuring the quality and reliability of containers, meeting regulatory requirements, and exceeding customer expectations.

The Bottle Top Load Tester Ultra by Pacorr is a game-changing solution for assessing the durability and strength of PET bottles. Its advanced features and compliance with international standards make it an invaluable tool for manufacturers aiming to enhance product quality and safety. Investing in this technology not only improves the quality of bottles but also boosts consumer confidence in the reliability and safety of the products they purchase.

To avoid these negative outputs, one must know how much compressive load their produced bottles can take. This way the user can ensure how much load, they need to put during storage or transit while they are stacked. Also, they can check if the PET bottles are meeting industry set standards. Bottle Top load tester, the digital model brings a high level of accuracy and precision in evaluating the buckling strength of PET bottles or containers.

| Aspect | Detail |

| Significance | Critical for ensuring the quality and safety of PET bottles |

| Application Industries | Beverage, Pharmaceutical, Cosmetic, Chemical, and Research & Development |

| Key Features | Precision, Versatility, User-Friendliness, Automation, Compliance |

| Compliance Standards | ASTM, ISO, and others |

| Benefits | Ensures product durability, customer satisfaction, and regulatory compliance |

FAQ's

Q1. What is a Bottle Top Load Tester?

A. A Bottle Top Load Tester is a precision testing instrument used to measure the resistance of bottles, jars, and containers against vertical compressive forces. This machine applies a controlled force to the top of the product to simulate the weight and pressure it may experience during storage or transportation, thereby assessing its strength and quality.

Q2. Why is Bottle Top Load Testing important?

A. Bottle Top Load Testing is critical for ensuring the quality and safety of bottle caps or closures. It helps prevent leaks, spills, or contamination, which can result in product recalls, customer complaints, and damage to brand reputation. Compliance with regulations and standards set by organizations like the ISO and FDA is also essential for market access and to avoid legal liabilities?.

Q3. How does a Bottle Top Load Tester work?

A. The Bottle Top Load Tester operates by placing a container on its top and applying a compressive load to the top surface using a plunger or probe. The load is gradually increased until the container deforms or breaks, and the maximum load at which failure occurs is recorded. This process helps determine the container's quality and strength.

Q4. What are the features and specifications of a good Bottle Top Load Tester?

A. A high-quality Bottle Top Load Tester should have features like adjustable load capacity, high load accuracy, variable test speed, different test modes (e.g., ramp, hold, release), a clear digital display, safety features (e.g., overload protection, emergency stop), compliance with relevant standards, and data storage and analysis capabilities.

Q5. In which industries is the Bottle Top Load Tester used?

A. The Bottle Top Load Tester is extensively used across various industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals, for quality control and testing of bottles, jars, and containers made of plastic, glass, or metal. It plays a crucial role in ensuring the containers' quality and reliability, meeting regulatory requirements, and satisfying customer expectations.

Q6. What is the price of the Top Load Tester?

A. The price of the Pacorr Top Load Tester typically ranges between ₹75,000 and ₹2,20,000 in India, depending on the model and features you select. For precise pricing and product specifications, it's recommended to contact Pacorr directly or visit their official website.

Write Your Review

Shlok Yadav

My company using this top load tester and getting accurate results.

Vishnu

Received best quality top load tester. I recommendation to others.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.