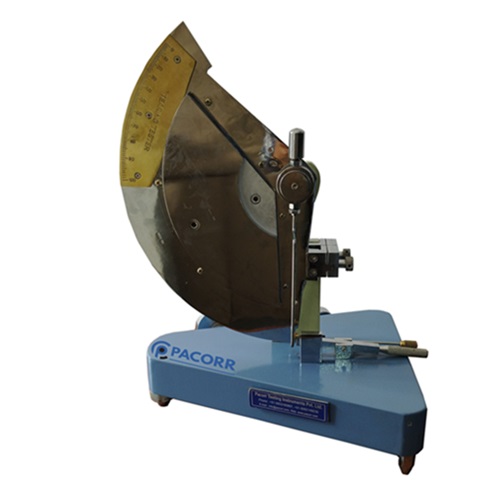

Rub Resistance Tester is a specialized instrument employed in quality control and testing procedures to evaluate the resistance of materials, such as printed graphics, labels, coatings, and textiles, to abrasion, rubbing, or friction. This critical assessment helps manufacturers and quality assurance professionals gauge the durability and long-term performance of materials exposed to wear and physical contact.

- Shipping Area: All over the world

- Model: PC-RRT01

The Rub Resistance Tester, offered by Pacorr, is a pivotal instrument in assessing the resistance of various materials like printed graphics, labels, textiles, and coatings against the effects of abrasion, rubbing, or friction. This testing is crucial for industries that prioritize the durability and the integrity of the material surface under physical stress.

What is a Rub Resistance Tester?

A Rub Resistance Tester, model PC-RRT01, is designed to measure the ability of packaging materials to withstand scuffing. This is especially vital for packaging industries where the appearance and readability of package information can significantly influence consumer perception and product value. The tester operates by simulating scuffing between two surfaces in a controlled environment to ascertain the material's durability under such conditions.

Specifications and Features

The Rub Resistance Tester comes equipped with features that ensure a comprehensive evaluation of material resistance. It includes variable speeds (21, 42, 85, & 106 cycles per minute), allowing for a range of testing scenarios. The machine is compliant with the ASTM 5264-92 standard, ensuring its acceptance and reliability across international markets. Additionally, it includes a digital cycle counter for precise measurement and an automatic shutdown feature once the test is completed, enhancing user convenience and test accuracy.

Applications Across Industries

While primarily utilized in the packaging industry, the Rub Resistance Tester's application extends to any sector concerned with material durability against friction and wear. From ensuring the longevity of printed labels and graphics to assessing textile resilience, this tester is a key component in quality control and product development processes.

Complementary Testing Instruments

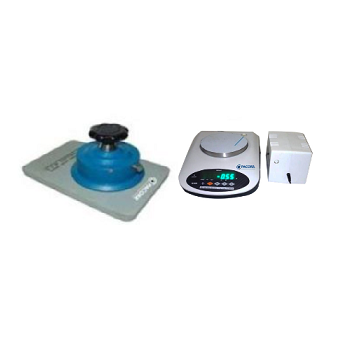

Pacorr also offers a variety of testing instruments relevant to industries utilizing rub resistance testers. Instruments such as the Puncture Resistance Tester, GSM Round Cutter with Weighing Balance, and Tearing Strength Tester provide a comprehensive toolkit for analyzing material durability and performance under various stress conditions.

The Rub Resistance Tester by Pacorr is an essential tool for manufacturers aiming to ensure their products maintain quality and durability when faced with physical abrasion or friction. With its precise testing capabilities, adherence to international standards, and a range of complementary instruments, Pacorr provides a robust solution for industries requiring thorough material testing.

Rub Resistance Tester is a highly precise testing instrument that is used by various industries to test the impact of rubbing when two surfaces rub against each other. Rubbing of two different surfaces against each other is termed as scuffing. The main usage of this instrument is in the packaging industries where the printed materials are tested for damage they can bear without defacing or compromising the print quality of the printed matter.

To evaluate the rub resistance (i.e. the ability to resist the damage done by rubbing) of labels and general printed matter, the instrument simulates the rubbing conditions in the laboratory to assess the competency of the packaging materials. Pacorr is a major manufacturer and supplier of Rub Resistance Tester that simulate scuffing by rubbing two printed surfaces against each other (face-to-face) in a circular motion. The speed and rubbing pressure is kept constant during the test. The testing instrument can be utilized in Paper & Packaging industries to measure and assess the colour transfer from printed or coated surfaces during the test. It is designed and produced in compliance to ASTM Standard. The digital counter given with the instrument gives the number of double strokes.

| Aspect | Detail |

| Purpose | Evaluate the durability of materials against abrasion, rubbing, or friction |

| Industries | Packaging, printing, textiles, coatings |

| Features | Speeds of 21, 42, 85 & 106 cycles per minute, ASTM 5264-92 standard compliance, digital cycle counter |

| Benefits | Ensures the longevity of printed materials, maintains print quality, aids in quality control |

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.