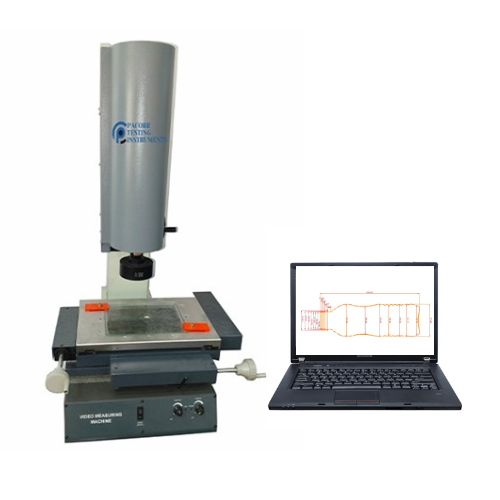

Profile Projector, a 2 Dimensional Vision Inspection System is a revolutionary technology used in many industries and research labs for product quality inspection. It is an automated Defect Inspection System used to assess the structural quality of products like dimensions, thickness, edges, and design properties. It helps manufacturers in increasing efficiency and offer objectified and accurate quality control by automating the inspection process which was earlier commenced manually.

- Shipping Area: All over the world

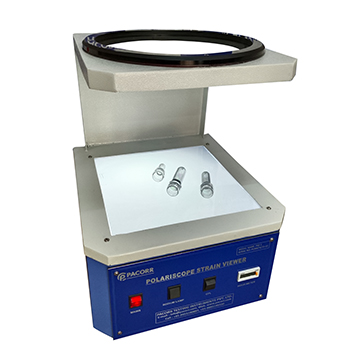

Pacorr's Profile Projectors are innovative instruments that have revolutionized quality inspection across various sectors. These systems utilize cutting-edge 2D vision inspection technology to examine the structural quality of products, focusing on dimensions, thickness, edges, and design properties. By automating the inspection process, they offer manufacturers a more efficient, accurate, and objectified approach to quality control.

Applications and Industries Served

The versatility of Profile Projectors allows them to be utilized in numerous fields, including packaging defect inspection, foreign element inspection, omission inspection, and product classification. They are particularly beneficial in industries where precision is paramount, such as automotive, plastics, rubber manufacturing, and even biomedical equipment production.

Technical Specifications and Features

Pacorr's Profile Projectors boast an array of impressive features that make them indispensable tools in modern manufacturing. These include a high-resolution CCD camera for clear imaging, optical magnification ranging from 0.7X to 4.5X, and LED illumination for enhanced visibility. The instruments are equipped with Sipmeas Software, ensuring precise measurements, and their design accommodates a maximum load capacity of 10 Kg.

Advantages of Using Profile Projectors

The primary advantage of employing Profile Projectors in manufacturing processes is their ability to significantly enhance product quality inspection. With features like one-click measurement for various geometries and the capacity for geometric tolerancing analysis, these projectors simplify complex inspections, making them ideal for high-speed production lines. Moreover, their user-friendly interface and continuous software updates facilitate ease of use and ongoing improvement.

Special Focus: Glass Inspection in the Chemical Industry

Profile Projectors are particularly effective in the inspection of glass containers used in the chemical and food & beverage industries. Given the critical nature of these containers for safe storage, the ability to detect any flaws—such as air bubbles, scratches, or structural weaknesses—is vital. Pacorr's Camera-Based Profile Projectors offer a detailed inspection capability, ensuring that glass containers meet the highest quality standards before being utilized in sensitive applications.

Pacorr's Profile Projectors represent a significant advancement in quality inspection technology. Their application across a broad spectrum of industries highlights their versatility and effectiveness in ensuring product quality. By integrating these instruments into their quality control processes, manufacturers can achieve higher efficiency, reduce the potential for manual inspection errors, and ultimately deliver superior products to their customers. For any organization prioritizing precision and quality, investing in a Profile Projector is a step towards future-proofing their manufacturing processes.

The profile projector boasts a user-friendly and intuitive interface that allows anyone to operate this machine without facing any complications. There are continuous program updates available for the system that ensures continuous improvement in the functioning and accuracy of the system. The instrument can be customized as per the customer's or industry requirements to ensure better applicability and efficiency. It provides advanced magnification to assess the quality of material in depth. It is also useful in the research & study of distinct material. The machine offers inspection of a wide range of physical properties of the material that covers maximum product manufacturing industries. It is a one-stop solution for all your quality inspection requirements.

| Aspect | Details |

| What is a Profile Projector? | An advanced 2D Vision Inspection System designed for automated defect inspection in various industries. |

| Applications | Used in manufacturing units for quality inspection of raw materials, production processes, and final products. Ideal for detecting defects in packaging, automotive parts, plastic and rubber components, and more. |

| Key Features | High-resolution imaging, advanced magnification technology, user-friendly interface, customizable as per industry requirements. |

| Specifications | Features include Sipmeas Software, a measuring range of 100 X 100 mm, high-resolution CCD camera, and LED illumination. |

| Benefits | Enhances manufacturing efficiency by providing accurate, objectified quality control and reducing manual inspection errors. |

FAQ's

Q1. What is a Profile Projector, and how does it work?

A. A Profile Projector, also known as an optical comparator or shadowgraph, is an instrument that uses optical, mechanical, and electronic technologies to magnify the surface features of a sample for visual inspection and measurement. It projects a magnified profile of the sample onto a screen using a high-intensity light source, a lens system, and a reflective mirror. The result is a detailed 2D image that can be analyzed for various characteristics such as shape, size, and surface defects.

Q2. What industries benefit most from using Profile Projectors?

A. Profile Projectors are widely used across various industries that require precise dimensional measurement and surface inspection. Key sectors include manufacturing (especially automotive, aerospace, and electronics), plastics and polymers, rubber production, biomedical equipment, and any field that deals with complex shape stampings, gears, cams, threads, or where meticulous quality control is paramount.

Q3. What types of measurements can be performed with a Profile Projector?

A. Profile Projectors can perform a variety of measurements including linear dimensions (length, width, height), angles, radii, diameters, and complex geometries. They are particularly adept at measuring the geometric tolerancing of manufactured parts, such as parallelism, perpendicularity, concentricity, and straightness. They also offer capabilities for inspecting a wide range of geometric shapes and features through magnification and visual inspection.

Q4. Can Profile Projectors be used for automated defect inspection?

A. Yes, many modern Profile Projectors are equipped with advanced vision inspection systems and software that enable automated defect inspection. These systems can quickly identify and categorize defects such as scratches, air bubbles, uneven surfacing, and alignment issues on a variety of materials. Automation enhances the efficiency and accuracy of quality control processes, significantly reducing the likelihood of human error.

Q5. How do Profile Projectors enhance quality control in the glass industry?

A. In the glass industry, Profile Projectors play a crucial role in ensuring the quality and safety of glass containers used in chemical and food & beverage sectors. They are capable of detecting minute defects that might compromise the integrity of the glass, such as air bubbles, scratches, and structural weaknesses. This precise inspection is vital for containers that need to withstand chemical reactions or preserve the quality of the contents they hold, thereby preventing potential hazards and ensuring compliance with industry standards.

Q6. What is the price of a Profile Projector?

A. The price of a Profile Projector in India can vary significantly based on the model, brand, and features it includes. Prices typically range from ₹50,000 to over ₹500,000. The price is influenced by factors such as the optical system, measurement accuracy, and additional features like digital readouts or software compatibility. For detailed pricing and to find a model that meets your specific needs, it's recommended to consult directly with suppliers or check company websites like pacorr.com.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.