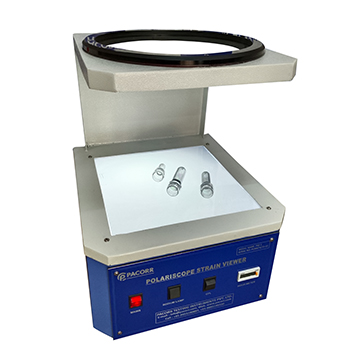

Polariscope Strain Viewer is used to evaluate stress and strain defects in PET Preforms to ensure high-quality production of PET containers. The machine is equipped with highly standardized light sources which when passed through preforms can help users detect even minute amounts of stress that may lead to bottle performance failure. The equipment is designed as per international acclaimed testing standards.

- Shipping Area: All over the world

- Model: PSP-1

The Polariscope Strain Viewer, provided by Pacorr, stands out as a critical instrument for ensuring the highest quality standards in PET container production. This device utilizes polarized light to reveal stress and strain defects that could compromise container integrity and performance.

Understanding the Polariscope Strain Viewer

The Polariscope Strain Viewer employs two primary light sources: Monochromatic CFL and Sodium Light. These lights, when passed through PET preforms, reveal the presence of stress and strain by reflecting or refracting in patterns that are visible to the observer. This method allows for the early detection of potential defects, ensuring that only the highest quality preforms proceed to the bottle-making stage.

Key Features and Specifications

- Model Name: PSP-1

- Power Requirement: 220V, Single phase, 50 Hz

- Light Sources: CFL Light & Sodium Light

This device offers sharp, clear optical viewing experiences and accommodates preforms of various shapes, enabling precise defect detection.

Application in Industries

The Polariscope is versatile, supporting quality assurance in the production of glass, PET preforms, and even gemstones. Its ability to detect structural anomalies in materials makes it invaluable across various sectors, including packaging, glass manufacturing, and gemology.

Advantages of Using Polariscope Strain Viewer

Quality Control

It is instrumental in identifying imperfections at an early stage, thus preventing costly production errors and ensuring that the final product meets industry standards.

Cost Savings

By detecting defects early, it reduces waste and avoids the expenses associated with producing substandard products.

Brand Reputation

Using such advanced quality control instruments helps maintain a brand's reputation for reliability and quality, essential for customer trust and loyalty.

Pacorr: A Commitment to Excellence

Pacorr's dedication to quality is evident in its wide array of testing instruments, designed to meet international standards. The Polariscope Strain Viewer is a testament to their commitment to innovation, precision, and customer satisfaction, as evidenced by their extensive global clientele, including major brands across various industries.

The Polariscope Strain Viewer from Pacorr represents a significant advancement in quality control technology for the PET container and glass industries. By providing precise, reliable data on material stress and strain, it plays a crucial role in ensuring the durability and safety of packaged products. As the demand for high-quality packaging continues to grow, tools like the Polariscope are essential for manufacturers committed to excellence and customer satisfaction.

To produce any PET containers, the manufacturer first produces its preform by blowing method. These preforms are tested for many aspects before they are transformed into bottles. One such quality defect in the development of stress & strain. During the production of preforms, due to inappropriate blowing methods, the preforms may develop stress marks, uneven surfaces, bubbles or strains on them. These defects can vary in shape and size and many not are visible by naked eyes. Doesn’t Matter how small, but these strain defects can lead to major defects in future. The bottle shape may not be as per requirement, they may not be stable, they may be too weak to store a few substances etc.

Polariscope Strain Viewer helps the user to view all kinds of stress or strain acquired by any preform. It is equipped with two standard-based lights, Monochromatic CFL Light and Sodium Light. These lights when passed through the sample preform, will either reflect or refract. Based upon their transparency and quality the lights will develop a pattern. This pattern can be viewed by the user and compared with the preform defect chart (available with the equipment). The pattern viewed when seen in the defect chart will define the quality standard of the specimen. The equipment provides a large viewing area that is suitable for distinct sized preforms. Accordingly, the user knows in advance whether the preform will sustain as a bottle or not.

| Feature | Description |

| Functionality | Detects stress and strain defects in PET preforms for high-quality containers. |

| Light Sources | Equipped with Monochromatic CFL Light and Sodium Light for detailed analysis. |

| Application | Essential for testing PET containers, glass, and gemstones. |

| Benefits | Ensures product durability, prevents defects, and saves production costs. |

| Technological Advancement | Offers computerized models for easy operation and precise analysis. |

| Customer Trust | Used by leading brands, ensuring commitment to quality and reliability. |

FAQ's

Q1. What is a Polariscope Strain Viewer, and how does it work?

A. A Polariscope Strain Viewer is a testing instrument that uses polarized light to detect stress and strain in transparent materials such as PET preforms, glass, and gemstones. It works by passing light through the sample material; the way this light reflects or refracts reveals the presence of stress patterns, which can be analyzed to assess the quality of the material.

Q2. Why is it important to detect stress and strain in PET preforms?

A. Detecting stress and strain in PET preforms is crucial because these defects can lead to performance failure in the final PET containers. Even minor imperfections can result in bottle shape irregularities, instability, or weakness, compromising the safety and quality of the contained product.

Q3. What types of light sources does the Polariscope Strain Viewer use?

A. The Polariscope Strain Viewer from Pacorr is equipped with two types of light sources: Monochromatic CFL Light and Sodium Light. These lights are chosen for their ability to produce clear, distinct patterns of stress and strain within the sample material, facilitating accurate defect detection.

Q4. Can the Polariscope Strain Viewer be used for materials other than PET preforms?

A. Yes, the Polariscope Strain Viewer is versatile and can be used to test a variety of transparent materials for structural anomalies in their refractive index. Apart from PET preforms, it is also used for examining glass and gemstones, making it valuable across different industries.

Q5. Is there a computerized version of the Polariscope available for more precise analysis?

A. Yes, Pacorr offers a highly advanced and accurate computerized model of the Polariscope Strain Viewer. This version is designed for ease of operation and provides precise analyses of the test results, enhancing the efficiency and reliability of the quality control process.

Q6. What is the price of a Polariscope Strain Viewer?

A. The price of a Polariscope Strain Viewer in India typically ranges from ₹50,000 to ₹2,50,000, depending on various factors such as brand, design sophistication, and included features. The price is influenced by the device's capabilities to detect and analyze strain patterns in transparent materials and the level of technological integration for enhanced visualization. For precise models and price details tailored to your specific requirements, consulting with reliable suppliers or checking specialized equipment websites like pacorr.com is recommended.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.