A moisture analyzer is a precise testing instrument designed to measure and regulate the moisture content in raw materials and finished products. It is an essential tool for industries where moisture levels play a critical role in product quality, such as food processing, pharmaceuticals, plastics, and packaging. By determining the exact percentage of moisture in materials, it helps manufacturers maintain consistency, prevent defects, and ensure regulatory compliance. These devices are easy to use, reliable, and indispensable for ensuring the longevity and performance of products. With a moisture analyzer, businesses can confidently deliver top-quality products to their customers.

- Shipping Area: All over the world

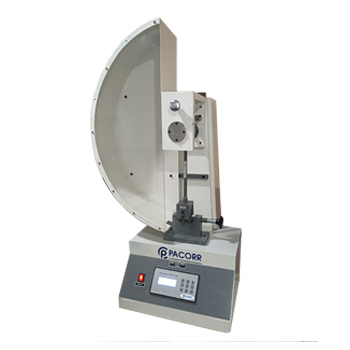

- Model: PC-AGS120

Controlling moisture content is a key factor in ensuring the quality and performance of materials across various industries. Excess or insufficient moisture can alter the physical and chemical properties of products, resulting in reduced durability, performance issues, or even spoilage. A moisture analyzer is a high-precision instrument that measures moisture levels in a wide range of materials, helping manufacturers regulate and optimize their production processes.

Industries like packaging, pharmaceuticals, food processing, and plastics rely on accurate moisture analysis to maintain product integrity and meet quality standards. For example, in packaging, moisture can compromise the strength of corrugated sheets and cardboard, affecting the safety of packaged goods. In the food industry, improper moisture levels can lead to spoilage or shorter shelf life. In plastics and polymers, excess moisture can change the chemical composition, weakening the final product.

The working principle of a moisture analyzer involves heating a sample to remove moisture and then calculating the weight difference before and after drying. This simple yet effective process allows for quick, accurate results. Pacorr’s moisture analyzers are built with advanced technology, ensuring precise measurements, ease of operation, and long-term reliability. They are a trusted solution for industrial laboratories and manufacturers striving for excellence in quality control.

Working Principle of a Moisture Analyzer

The working principle of a moisture analyzer revolves around determining the difference in weight before and after the removal of moisture from a sample. The process can be summarized in four steps:

- Sample Placement: A small, pre-weighed sample of the material is placed on the analyzer's weighing pan.

- Drying: The instrument uses a controlled heating system, such as halogen or infrared lamps, to evaporate the moisture in the sample.

- Weight Measurement: The analyzer measures the weight of the sample continuously during the drying process until it stabilizes.

- Moisture Content Calculation: The difference in weight is used to calculate the percentage of moisture present in the sample.

This straightforward and effective method ensures rapid, accurate measurements. Advanced moisture analyzers, such as those offered by Pacorr, integrate modern sensors and automation to deliver consistent results while being simple to operate.

What is a Moisture Analyzer?

A moisture analyzer is a specialized device used to measure the moisture content of materials with high precision. The device is widely employed in industries such as food, packaging, pharmaceuticals, plastics, textiles, and paper. It operates by removing moisture from a sample through controlled heating and then calculating the percentage of moisture based on weight changes.

These instruments are essential for quality control processes, helping manufacturers ensure that their products meet required specifications. By providing reliable data on moisture levels, moisture analyzers enable businesses to optimize production, prevent material defects, and adhere to industry standards.

Why is a Moisture Analyzer Used?

A moisture analyzer is used for a variety of critical applications, including:

- Quality Assurance: It ensures that materials meet industry-specific moisture content requirements, resulting in high-quality end products.

- Minimizing Material Defects: By identifying and controlling moisture levels, manufacturers can prevent issues such as weakening, spoilage, or chemical instability.

- Regulatory Compliance: Many industries have strict guidelines regarding acceptable moisture levels, and moisture analyzers help maintain compliance.

- Cost Efficiency: By optimizing moisture levels, businesses reduce waste and improve production efficiency.

- Improving Shelf Life: In food and pharmaceutical industries, moisture control prevents spoilage and extends product longevity.

Problems Solved via Moisture Analyzer

Moisture analyzers help address several challenges faced by manufacturers:

- Weakened Materials: Excess moisture can compromise the strength of packaging materials, such as corrugated sheets and cardboard, leading to product damage.

- Food Spoilage: High moisture levels in food products can promote microbial growth, reducing shelf life and quality.

- Chemical Instability: Plastics, polymers, and pharmaceuticals can undergo chemical changes due to moisture, affecting their integrity and performance.

- Production Losses: Improper moisture levels can cause defects in materials, leading to rejected batches and higher production costs.

- Compliance Issues: Failure to meet moisture content standards can result in regulatory penalties and damage to brand reputation.

Benefits of Using a Moisture Analyzer

Using a moisture analyzer offers several key advantages:

- Enhanced Accuracy: Modern moisture analyzers provide precise and reliable measurements, ensuring consistent quality.

- Quick Results: These instruments are designed for rapid moisture analysis, enabling faster decision-making during production.

- Ease of Use: Intuitive interfaces and automation make moisture analyzers simple to operate, even for new users.

- Improved Product Quality: Proper moisture control ensures that materials perform as expected, enhancing the overall product experience.

- Versatility: Moisture analyzers can be used for a wide range of materials, including solids, liquids, powders, and more.

- Cost Savings: By preventing moisture-related defects, businesses can avoid material wastage and reduce production losses.

- Regulatory Compliance: Moisture analyzers help manufacturers meet strict industry standards, ensuring legal and commercial viability.

FAQ's

Q1: What material can be analyzed with the help of a Moisture Analyzer?

A. A moisture analyzer is a versatile instrument capable of analyzing a wide range of materials. It is commonly used to measure moisture content in solids such as powders, granules, and grains (e.g., flour, sugar, and chemical powders). Semi-solid samples like pastes, gels, and adhesives can also be analyzed. Additionally, it is effective for liquids, including oils, creams, and other fluid-based materials. For industrial applications, moisture analyzers are often used for materials like plastics, polymers, paper, textiles, and wood. This versatility makes moisture analyzers a vital tool in industries such as food processing, pharmaceuticals, packaging, chemicals, and construction.

Q2: What mechanism is used for heating the sample in the instrument?

A. Moisture analyzers use advanced heating mechanisms to ensure efficient and accurate drying of the sample. Most instruments rely on halogen lamps, infrared heating, or metal heating elements to evaporate moisture from the sample. Among these, halogen lamps are widely preferred due to their ability to provide quick, uniform heating without causing damage to the material being tested. This even distribution of heat ensures reliable and repeatable results, making halogen-based systems highly suitable for a wide range of applications.

Q3: What is the temperature range of the instruments?

A. The temperature range of moisture analyzers typically falls between 50°C and 200°C, making them suitable for analyzing a wide variety of materials. Some advanced models are capable of operating at temperatures beyond this range to accommodate specific testing requirements. The flexibility of the temperature settings ensures that the instrument can be adapted to test materials with varying moisture content and drying needs, making it a valuable tool across diverse industries.

Q4: How much time does it take to completely heat up the heating chamber?

A. Moisture analyzers are designed to operate efficiently and provide quick results. On average, the heating chamber takes approximately 1 to 5 minutes to fully heat up, depending on the target temperature and the model of the instrument. Halogen-based heating systems, in particular, are known for their rapid heating capabilities, which are ideal for time-sensitive industrial applications where quick and accurate results are essential.

Q5: Is the instrument available with computer connectivity?

A. Yes, modern moisture analyzers often come equipped with computer connectivity features to enhance usability and data management. Most models include USB or RS232 interfaces, enabling users to transfer test data directly to a computer for detailed analysis and report generation. This connectivity not only simplifies the process of maintaining digital records but also ensures compliance with quality control standards. Additionally, the ability to integrate with laboratory management systems boosts operational efficiency, making moisture analyzers a smart choice for businesses that require seamless data handling and reporting.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.