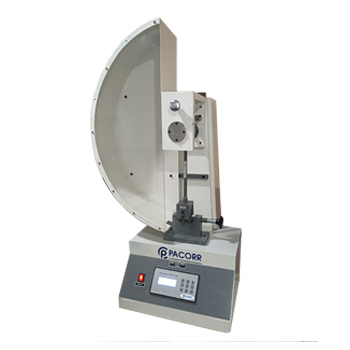

Summary: The Melt Flow Index Tester Method A, B & C (MFR and MVR) is a sophisticated instrument designed to measure the flowability of thermoplastic polymers when they are melted under standardized conditions. This instrument is a vital tool in the plastics industry, used extensively for the characterization of polymer materials. By conducting melt flow tests according to specific standards such as ASTM D1238, ISO 1133-2, IS 2530, and ISO 13360 Part 4, manufacturers can predict how a polymer will behave during processing, ensuring quality control and aiding in product development.

- Shipping Area: All over the world

- Model: PCMVR

This tester is designed to comply with Method A, B & C for MFR and MVR, providing a comprehensive range of testing capabilities. The temperature range of the device spans from ambient to 400°C, with a least count of 0.1°C and an accuracy of ± 0.5%. This high level of precision is maintained by a microprocessor-based PID temperature controller, which ensures consistent and accurate heating.

The instrument is equipped with an inbuilt digital timer with a range of up to 999.9 seconds and an auto-cutting facility, which is crucial for maintaining precise testing intervals. The PLC controlled touch screen HMI offers an intuitive interface for setting parameters and monitoring tests, enhancing user convenience and operational efficiency. Additionally, the storage of test results in a USB flash drive simplifies data management and facilitates easy transfer of information.

The test chamber features an electrical cartridge heater with PID-based digital temperature control, along with corrosion-resistant pistons and barrels. This construction ensures durability and reliable performance even with chemically aggressive materials. The tungsten carbide die, known for its hardness and wear resistance, is a standard feature, ensuring long-term accuracy and reliability of the test results.

For versatility, the tester comes with various test weights, including 2.16 kg and 5 kg hard chrome plated weights. The die dimensions are precisely maintained at 8.0 mm ± 0.025 mm in length and 2.095 ± 0.005 mm in bore diameter, adhering to standard specifications. The tester can perform both melt flow rate (MFR) and melt volume rate (MVR) tests, providing comprehensive data on polymer flow properties.

The instrument also includes a range of accessories such as orifice, piston, material charger, barrel cleaner, orifice cleaner, and sample cutter, ensuring efficient operation and maintenance. The powder-coated finish of the device enhances its durability and resistance to environmental factors.

In conclusion, the Melt Flow Index Tester with Methods A, B & C (MFR & MVR) and PLC Controlled Touch Screen is an essential tool for the plastics industry. It offers precise measurement of polymer flow properties, aiding in quality control, product development, and process optimization. Its advanced features, compliance with international standards, and user-friendly design make it an indispensable asset for any polymer laboratory or manufacturing unit.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.