A Melt Flow Index Tester (MFI Tester) is a sophisticated tool used to assess how thermoplastic materials behave under specific heat and load conditions. This test is pivotal in the polymer industry, helping manufacturers gauge the melt flow rate (MFR) of materials like polyethylene, polypropylene, and other plastics. Such insights are essential for maintaining product quality, ensuring consistency, and adhering to strict manufacturing standards.

- Shipping Area: All over the world

- Model: PCMFIT-1

Understanding how an MFI Tester works is straightforward: the device heats a polymer sample until it melts, creating a controlled environment for testing. Once molten, the material is pushed through a narrow die under a specified load. By measuring the flow rate—usually expressed as grams per ten minutes (g/10 min)—the machine provides critical insights into the polymer's viscosity, molecular weight, and suitability for processes like injection molding, extrusion, or blow molding.

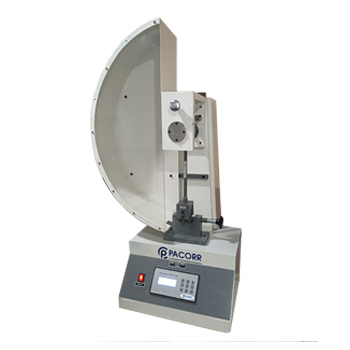

Pacorr’s Melt Flow Index Tester is designed to deliver unmatched accuracy and reliability. Its advanced features, including digital temperature controls, automated timing, and interchangeable weights, make it versatile enough for a range of testing needs. Crafted with durable materials, it’s built to handle high-volume testing effortlessly while incorporating safety measures to protect operators. Plus, its user-friendly interface ensures even complex procedures feel straightforward for lab teams.

Integrating an MFI Tester into your quality control process isn’t just about compliance—it’s about working smarter. With precise material insights, manufacturers can optimize production, reduce waste, and elevate product performance. Industries like automotive, packaging, and consumer goods rely on tools like this to meet rigorous standards and deliver top-notch results.

For businesses that value precision and efficiency, a reliable Melt Flow Index Tester is an indispensable asset. Pacorr offers a solution that pairs cutting-edge design with practical functionality, helping you tackle the challenges of today’s polymer industry head-on.

Specification:-

- Temperature Controller: Microprocessor based Digital Temperature Controller

- Temperature Range: Upto 400 deg. C

- Resolution: 0.1 deg. C

- Accuracy: +/- 0.1 % F.S.D.

- Timer: Microprocessor based Digital Timer with range up to 999.9 Seconds and having Preset facility and buzzer output.

- Weights: 2.16 Kg & 5 Kg hard chrome plated weights.

- Accessories: Orifice, Piston, Barrel Cleaner, Orifice cleaner etc.

- Sample Cutting: Auto-Cut

- Paint: Powder Coating.

- Power: 230V AC, 50 Hz

- Amperes: 4 Amps.

- Table Top Model

Features:-

- Sample Cutting, Auto cutting

- Automated Sample Cutting facility

- Comes with digital temperature controller and indicator

- Duly powder coated outer body for long life and corrosion resistance

- Comes with different load weights

- Greater accuracy with digital preset timer

FAQ's

Q1. What is a Melt Flow Index Tester, and why is it important?

A. A Melt Flow Index Tester (MFI Tester) is a laboratory instrument designed to measure the flow rate of molten thermoplastic materials under specific heat and load conditions. This test evaluates the melt flow rate (MFR), a critical indicator of a polymer’s viscosity and molecular weight. The MFR data ensures that manufacturers can maintain consistency in material quality and performance. This makes the MFI Tester an essential tool for industries such as packaging, automotive, and consumer goods, where high-quality plastic materials are a must.

Q2. How does a Melt Flow Index Tester work?

A. The MFI Tester works by heating a small sample of polymer in a temperature-controlled barrel until it melts. Once molten, the material is pushed through a calibrated die using a specific load or weight. The amount of polymer extruded in ten minutes is recorded as the melt flow index (MFI), expressed in grams per ten minutes (g/10 min). This straightforward yet precise measurement provides insights into the material’s flow characteristics, helping determine its suitability for manufacturing processes like injection molding, extrusion, and blow molding.

Q3. Which industries benefit from Melt Flow Index testing?

A. Melt Flow Index testing plays a vital role in industries where the quality and consistency of thermoplastics are critical:

- Automotive: Ensures materials meet durability and performance standards for components like dashboards and bumpers.

- Packaging: Verifies material strength and flexibility for products such as containers and films.

- Construction: Guarantees that piping and insulation materials meet regulatory requirements.

- Consumer Goods: Helps maintain quality in everyday products like toys and household appliances.

Q4. How does Melt Flow Index testing improve quality control?

A. Incorporating MFI testing into quality control processes helps manufacturers detect deviations in polymer properties early, ensuring that all production batches meet the required specifications. For example:

- Identifying changes in viscosity or molecular weight prevents defects in finished products.

- Monitoring the melt flow rate ensures the material behaves predictably during molding or extrusion processes.

- Reducing material waste and minimizing production downtime boosts overall efficiency and cost savings.

Q5. What factors can impact Melt Flow Index test accuracy?

A. Several factors can affect the precision of MFI test results:

- Sample Preparation: Contaminated or improperly cut samples can lead to inconsistent readings.

- Die Dimensions: Variations in die size or damage can alter flow measurements.

- Temperature Control: Fluctuations in heating accuracy impact the material's melt behavior.

- Equipment Calibration: Regular calibration ensures the machine measures accurately.

- Operator Errors: Inconsistent loading or timing can lead to unreliable results.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.