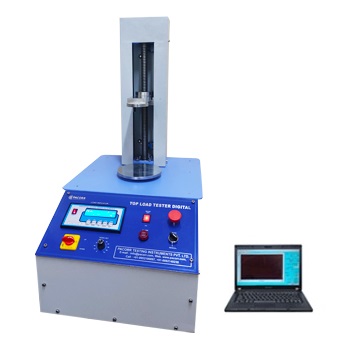

Magnetic Wall Thickness Gauge is an advanced, precision tool designed to measure the thickness of ferrous and non-ferrous materials without causing damage. Leveraging magnetic technology, it delivers accurate and reliable readings, making it essential for industries like manufacturing, quality control, and research. Compact, durable, and easy to use, this gauge ensures compliance with strict industry standards while streamlining measurement tasks. Whether working with metals, plastics, or composites, the Pacorr Magnetic Wall Thickness Gauge guarantees efficiency and accuracy, empowering professionals to maintain superior product quality. Experience the perfect balance of innovation and reliability with Pacorr's trusted solution.

- Shipping Area: All over the world

- Model: PCMWTG-D

The Pacorr Magnetic Wall Thickness Gauge is a cutting-edge instrument engineered for precision and versatility. This device allows users to measure the thickness of various materials, including metals, plastics, and composites, without causing surface damage. Using advanced magnetic principles, it provides highly accurate readings that are indispensable for applications in manufacturing, construction, research, and quality control.

Designed for professionals, the gauge features a robust and ergonomic build, ensuring it withstands demanding industrial environments while remaining user-friendly. Its compact size makes it portable, allowing for convenient on-site measurements. The intuitive interface minimizes training time, making it accessible even for those new to thickness measurement.

What sets this tool apart is its ability to comply with rigorous industry standards, helping businesses maintain consistent quality and avoid costly material defects. From evaluating pipe thickness in construction to inspecting product uniformity in production lines, the Pacorr Magnetic Wall Thickness Gauge is a reliable partner for achieving precision and efficiency.

Benefits

- Non-Destructive Testing: Measures material thickness without compromising its structural integrity.

- High Accuracy: Delivers precise readings for consistent quality control.

- Versatility: Suitable for various materials, including metals, plastics, and composites.

- Durable Design: Built to endure harsh industrial environments.

- Portable and Compact: Easy to carry and operate on-site.

- Cost-Efficient: Helps identify material defects early, reducing waste and production delays.

- User-Friendly Interface: Simplifies operations for professionals and beginners alike.

Features

- Advanced Magnetic Technology: Ensures accurate, reliable measurements across diverse applications.

- Ergonomic Build: Designed for comfort during prolonged use.

- Intuitive Display: Provides clear and quick readings.

- Robust Construction: Durable materials ensure long-term performance.

- Wide Application Range: Measures ferrous and non-ferrous materials.

- Portable Design: Lightweight and compact for easy transport.

- Compliance Standards: Meets international quality and safety requirements.

The Pacorr Magnetic Wall Thickness Gauge is a vital tool for professionals seeking precision and efficiency in material thickness measurement. Its innovative design, combined with its reliability and ease of use, makes it a standout choice across various industries. With Pacorr, you don’t just measure; you elevate quality assurance to new heights. Trust in Pacorr to deliver excellence every time.

FAQs

Q 1. What materials can the Magnetic Wall Thickness Gauge measure?

A. The Magnetic Wall Thickness Gauge is versatile and can measure a wide range of materials, including ferrous materials such as steel and iron, as well as non-ferrous materials like aluminum, plastics, and composites. This flexibility makes it suitable for applications in industries like manufacturing, construction, and quality assurance, where diverse material testing is essential.

Q 2. Is the gauge suitable for harsh industrial environments?

A. Yes, the Pacorr Magnetic Wall Thickness Gauge is specifically designed to perform in challenging industrial settings. Its robust construction includes durable materials and a resilient design to resist wear and tear, making it reliable even in environments with high temperatures, dust, or mechanical stress. This ensures that you get consistent results without compromising the tool's longevity.

Q 3. Does it require special training to operate?

A. No, the gauge is built with user convenience in mind. Its intuitive interface and straightforward design eliminate the need for extensive training. Even if you're a beginner, you'll find the device easy to understand and operate. For advanced users, the gauge also provides options for fine-tuning settings, ensuring it meets a variety of professional requirements.

Q 4. Can this gauge be used for quality control?

A. Absolutely. The Magnetic Wall Thickness Gauge is a critical tool for quality control processes in multiple industries. It helps detect material inconsistencies, monitor product uniformity, and ensure compliance with international standards. By catching defects early in the production process, the gauge helps reduce waste and prevent costly errors, ultimately improving overall product quality.

Q 5. What makes the Pacorr gauge different from others?

A. The Pacorr Magnetic Wall Thickness Gauge stands out for its advanced magnetic technology, ensuring unparalleled accuracy and reliability. Its portable and lightweight design makes it ideal for on-site measurements, while its compliance with industry standards guarantees trustworthy results. Additionally, the ergonomic build ensures user comfort, even during prolonged use, setting it apart from competitors that may compromise on convenience or durability.

Q 6. Can it measure curved or irregular surfaces?

A. Yes, the gauge is designed to adapt to various surface types, including flat, curved, or irregular surfaces. This adaptability is crucial for industries like automotive or construction, where components often come in complex shapes. Its precision ensures accurate measurements regardless of the material’s geometry.

Q 7. How does the gauge contribute to cost savings?

A. By providing precise measurements and identifying material defects early, the gauge minimizes waste and prevents costly rework or production delays. Its durability also reduces the need for frequent replacements, making it a long-term investment that enhances efficiency and profitability in industrial operations.

Q 8. Does it come with a warranty or support services?

A. Yes, Pacorr offers comprehensive support for its Magnetic Wall Thickness Gauge, including a warranty for manufacturing defects. Customers also benefit from detailed manuals and responsive customer service to address any issues or questions, ensuring a seamless user experience.

Q 9. How much does a Magnetic Wall Thickness Gauge typically cost?

A. The cost of a Magnetic Wall Thickness Gauge in INR typically ranges from approximately 75000 to 800000 INR, depending on the features, accuracy, and brand. For precise pricing, it's best to check with specific suppliers or manufacturers in India to find a model that suits your requirements and budget.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.