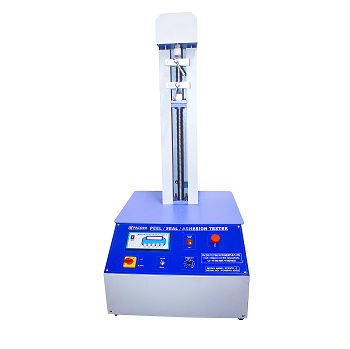

The Laboratory Heat Sealer from Pacorr is a precision instrument designed to deliver consistent, high-quality seals for packaging materials. Ideal for testing and quality assurance, this heat sealer ensures reliable packaging integrity through controlled sealing parameters, meeting rigorous industry standards for durability.

- Shipping Area: All over the world

- Model: PCLHS-150

The Laboratory Heat Sealer is an essential tool for ensuring the quality of seals in packaging materials. Built for accuracy, it allows for precise control over temperature, pressure, and dwell time, providing consistent seals that meet specific quality requirements. This precision makes the heat sealer indispensable for laboratories focused on quality assurance in packaging, offering a reliable method for testing seal strength under varied conditions.

The device is engineered to accommodate a variety of materials, including plastic films, foils, and laminates. Its intuitive interface and customizable settings simplify operation, enabling efficient adjustments to meet the unique needs of each material type. This adaptability allows professionals to establish optimal sealing conditions that prevent potential packaging failures and maintain product safety.

Pacorr’s Laboratory Heat Sealer is designed for longevity and consistent performance. Its robust construction ensures reliable results, supporting laboratories in maintaining high standards for packaging integrity. For quality control applications, this heat sealer is an invaluable asset, reinforcing confidence in packaging performance and contributing to better product protection.

Specificaiton:

- Model: PCLHS-150

- Sealing Temperature Range: Ambient to 300 0C.

- Temperature Controller: PID

- Instrument Temperature range: 0 – 400 0C

- L.C. 0.1ËšC and Accuracy of 0.2 0C.

- Dwell Time: 0.1 to 999.9 seconds.

- Pressure: 0.05 to 0.7 MPa. Operated by switch OR Footswitch.

- Seal surface: 150mm x 15mm &300 mm X 15 mm (Straight Line)

- Air Input: 0.7 MPa

- Table top Model

- Power: 230 V AC, 50 Hz

Features:-

- Seal Pattern: Straight line

- Microprocessor based display for accurate test results

- Highly accurate test results under pneumatic pressure control.

- Single Pushbutton operation after setting PID temperature and time

- Strong heating jaws for performing tests

- Bright LED display for temperature and timer

- PID temperature controller for highest level of controls and repeatability

- Digital Preset timer

- Guide rod mechanism for efficient control of sealing

- Standards: ASTM F 2029

FAQ's

Q1. What materials can be sealed with a Laboratory Heat Sealer?

A. A Laboratory Heat Sealer is capable of sealing various thermoplastic materials effectively. These materials include plastic films, polyethylene, polypropylene, and laminated sheets, among others. Its adjustable heat settings make it adaptable for sealing materials of different thicknesses and compositions. This flexibility ensures its suitability for a wide range of packaging applications, whether in testing environments or practical production use.

Q2. How does the seal strength of a Laboratory Heat Sealer compare to other sealing methods?

A. The seal strength achieved using a Laboratory Heat Sealer surpasses many other sealing techniques because of its precise control over critical factors like temperature, pressure, and sealing time. These controls ensure a uniform seal every time, which is crucial for protecting the contents and maintaining the product's safety. Additionally, standardized heat seal tests can be conducted to verify the quality and durability of seals, making them highly dependable.

Q3. Can a Laboratory Heat Sealer be used for both small-scale and industrial applications?

A. A Laboratory Heat Sealer is versatile enough to handle both small-scale laboratory tasks and larger industrial applications. Its scalability allows seamless integration into various workflows, whether it’s being used for experimental packaging tests or high-volume production lines. This adaptability makes it a valuable tool in multiple settings, regardless of the project's size or complexity.

Q4. How does a Laboratory Heat Sealer ensure compliance with packaging standards?

A. A Laboratory Heat Sealer incorporates advanced controls for sealing parameters, such as temperature and pressure, which are essential to meet stringent packaging standards. These features enable precise adjustments that align with industry-specific regulations. By allowing for the execution of standardized heat seal tests, the device ensures that the packaging not only adheres to but often exceeds required criteria for durability and seal integrity.

Q5. What are the maintenance requirements for a Laboratory Heat Sealer?

A. To keep a Laboratory Heat Sealer operating efficiently, routine maintenance is essential. This includes regularly cleaning the sealing jaws and the surrounding area to remove any residue that might accumulate over time. Inspecting and replacing worn sealing elements is also important to maintain consistent performance. Following the manufacturer’s maintenance recommendations helps extend the device’s lifespan and ensures reliable operation during sealing tasks.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.