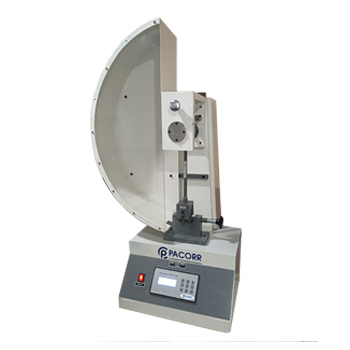

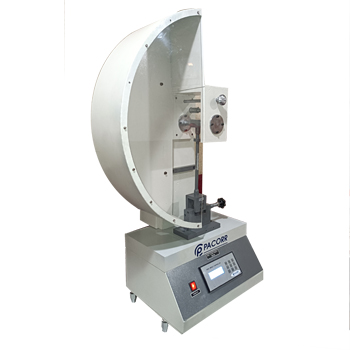

Summary: Izod/Charpy impact tester is a device used to measure the impact resistance of a material. It works by applying a sudden force to a sample of the material, and measuring the amount of energy required to break or deform the sample. The Impact tester is capable of performing both Izod /Charpy Impact Test. The equipment is beautifully designed that precisely conforms to international test standards and allows easy testing procedure as well as delivering user and product safety features.

- Shipping Area: All over the world

- Model: PCICIT-1

Specification-

- Impact Energy :0-25 Joules

- Release angle of pendulum: 150 Degree

- Micro controller: With setting of sample dimension, error of machine and selection of Standard of test process (IS, ISO or ASTM) and hammer selection with Direct display of impact energy in joules and Impact Strength in J/mt & J/mt² and corresponding angle in degrees on digital indicator with selection of hammer.

- 4 Line LCD display with 10 test memory with Average result of selected test.

- Indication to select low or high value of Hammer during test.

- Indication to conduct test by microcontroller.

- Faulty sensor indication on LCD display.

- Easy, Safe and maintenance free release mechanism for Hammers.

- Easy interchangeability of hammers during test.

- Hammers: 2 nos. of Powder coated hammers of one each for Charpy & Izod Tests

- Supplied with Incremental plates would be supplied which could be attached to these hammers to convert them in to hammers for 2nd, 3rd, 4th & 5th scale.

- Screw (Vise) type powder coated bench for Izod test and Sample holding stand for Charpy sample test as per standard.

- Paint: Powder Coated.

- Power:230 V AC, 1 Phase, 60 Hz. (OR AS PER REQUIREMENT)

Features:

- Robust construction ensuring high durability and consistent test accuracy

- Designed for precise impact energy measurement (Izod and Charpy tests)

- Easy-to-use digital controls and intuitive interface

- High-resolution digital display for clear readability of results

- Complies fully with ASTM D256, ASTM E23, ISO 179, and ISO 180 standards

- Automatic pendulum braking system for enhanced safety

- Precise energy calculations with minimal human intervention

- Reliable performance for plastics, composites, metals, and other materials

- Efficient pendulum impact mechanism providing repeatable test outcomes

- Advanced safety features including protective enclosures

- Low maintenance design reduces operational downtime

- Suitable for quality control in automotive, aerospace, and manufacturing sectors

- Adjustable pendulum heights for diverse testing applications

- Strong mechanical design minimizes vibrations for accurate testing results

- User-friendly calibration ensuring quick setup and operation

The Izod/ Charpy Impact Tester is an essential instrument in assessing material resistance to impact, providing invaluable data across various sectors such as aerospace, automotive, and construction. It plays a pivotal role in material testing by employing the Izod and Charpy methods, each focusing on how materials behave under sudden impact forces. This guide delves into the significance, applications, and operational principles of the Izod Impact Tester, highlighting its critical role in ensuring the safety and reliability of materials used in numerous applications.

What is an Izod Impact Tester?

The Izod Impact Tester is a specialized instrument designed to determine a material's resistance to impact. It operates by measuring the energy absorbed by a notched specimen when struck by a pendulum. This test is crucial for materials subjected to dynamic stresses, where understanding how they react under impact conditions is vital for ensuring product safety and integrity.

The Izod vs. Charpy Test Methods

Izod Test: Involves a vertically clamped notched specimen struck by a pendulum. The energy absorbed during the fracture indicates the material's impact resistance.

Charpy Test: Similar to the Izod test but with the specimen placed horizontally and supported at both ends. It also measures the absorbed energy during fracture.

These methods provide insights into a material's toughness, contributing significantly to quality control, material selection, and product development processes.

The Izod Impact Tester is instrumental across various sectors.

- Aerospace and Automotive: For testing materials used in aircraft components and car parts.

- Construction: To evaluate building materials like concrete and steel for impact resistance.

- Manufacturing: Ensures consumer products' materials meet required durability and safety standards.

- Research and Development: Helps in developing and testing new materials for advanced applications.

Operational Principle and Benefits

The testing procedure involves several steps, starting from specimen preparation to analyzing and recording the results. These tests are conducted following specific standards (such as ASTM D1204, ASTM D256, ASTM D883) to ensure accuracy and reliability in the testing process.

Key Benefits:

- Material Selection: Enables the choice of materials that meet specific impact resistance requirements.

- Quality Control: Acts as a quality assurance tool, ensuring materials and products adhere to required standards.

- Innovation and Product Development: Aids in the development of new materials and products with improved impact resistance.

The Izod Impact Tester is a cornerstone in the field of material testing, offering detailed analysis and evaluation of a material's ability to withstand impact forces. Its applications across various industries underscore its importance in ensuring the safety, durability, and reliability of materials and products. By providing a quantifiable measure of impact resistance, the Izod Impact Tester plays a vital role in material selection, quality control, and the advancement of material science.

Izod/ Charpy Impact tester equipment is used in plastic industries to measure the amount of energy required to break a plastic specimen by striking it through a free fall pendulum.

Plastics are used for manufacturing a variety of products for domestic and industrial use. They are used for making products such as bushes, switches, gaskets and many more. As these plastic products are used in some very crucial applications, the quality of these plastic products must be of utmost level. This is why the manufacturers must conduct proper testing of the products with great accuracy and precision.

During their end-use, they tend to experience different types of forces and impacts that can damage the material and lead to the absolute failure of the plastic. Hence, it is vital for the manufacturer or the designer that the material they are producing must be strong enough to bear the impacts or forces they may have in their future use.

The most renowned and popular test method that is globally accepted to evaluate the impact strength of plastic is “Izod/Charpy Impact Test”. Izod and Charpy are two distinct methods to evaluate the impact strength. To perform the test, the sample is notched at a defined depth and measurement. This notched material is kept and tightened in the equipment. A pendulum that may be a bar or a circular plate is fixed at a defined height and released on the specimen with full force. The Impact absorbed by the plastic material defines its quality.

Though both Izod and Charpy tests are equally renowned to determine the toughness of a material, there is a major difference between them - the way the specimen is placed. For the Izod method, the sample is kept vertical, with the notch facing the pendulum impact and in Charpy, the specimen is placed horizontally with the notch facing away from the pendulum. The test usually prefers the notched specimen but can be performed on in notched material too.

The Izod/Charpy Impact Tester is designed according to the standards prescribed in the ASTM D1204, ASTM D256, ASTM D883 which ensures that the instrument can give the best accuracy of testing data and deliver better quality to the customers.

| Feature | Details |

| Purpose | Evaluates the impact resistance of materials, especially metals and plastics, using the Izod and Charpy methods. |

| Applications | Widely used across aerospace, automotive, construction, manufacturing, and research industries. |

| Operation | Measures energy absorbed by a specimen when struck by a pendulum, providing insights into material toughness and durability. |

| Benefits | Assists in material selection, quality control, and product development by ensuring safety and reliability. |

| Standards | Complies with ASTM D1204, ASTM D256, ASTM D883 for accurate testing data and quality assurance. |

FAQ's

Q1. What is the difference between Izod and Charpy impact tests?

A. Both Izod and Charpy tests measure the impact resistance of materials, but they differ mainly in the specimen's placement and orientation. In the Izod test, the specimen is clamped vertically, and the pendulum strikes a notched section of the specimen. In contrast, the Charpy test involves a horizontally placed specimen, supported at both ends, with the pendulum striking the notched section from above.

Q2. How is the energy absorbed by the specimen measured in an Izod /charpy impact test?

A. The energy absorbed is measured by the difference in the height of the pendulum's swing before and after striking the specimen. This difference represents the amount of energy absorbed by the specimen during fracture. The result is typically expressed in joules or foot-pounds.

Q3. Can the Izod/ charpy impact tester be used for materials other than plastics and metals?

A. Yes, while the Izod/ charpy impact tester is primarily used for testing plastics and metals, it can also be used for other materials like composites and ceramics, provided the material can be fashioned into the required specimen shape and complies with the test standards.

Q4. What are the key benefits of using an Izod/ charpy impact tester in material testing?

A. The key benefits include enabling material selection by assessing impact resistance, ensuring quality control by verifying material consistency, aiding in research and development by testing new materials, and evaluating product performance to ensure safety and durability.

Q5. How often should an Izod/ Charpy impact tester be calibrated?

A. The calibration frequency of an Izod/charpy impact tester depends on the volume of testing and the precision requirements of the testing procedures. However, it's generally recommended to calibrate the tester at least once a year or after any major repair or adjustment to ensure accurate and reliable test results.

Q6. What is the price of an Izod/Charpy Impact Tester?

A. The price of an Izod/Charpy Impact Tester in India typically ranges from ₹1,00,000 to ₹3,00,000, depending on the model, specifications, and brand. For precise pricing, it’s advisable to contact the manufacturer or supplier directly.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.