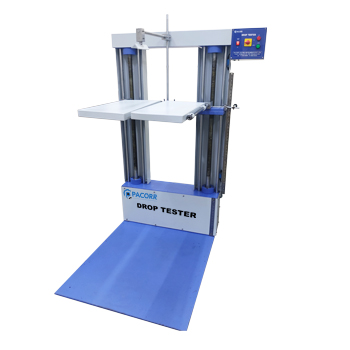

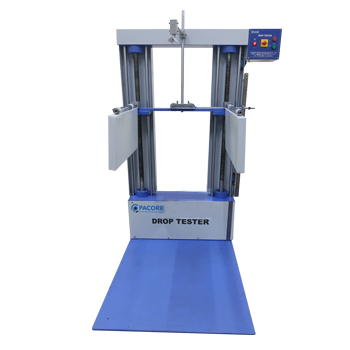

Summary: Drop Tester is an essential quality assurance tool designed to evaluate the durability and resilience of packaging materials and products. By accurately simulating real-world drops and impacts, this device ensures products withstand transportation and handling, significantly reducing damage and customer complaints.

- Shipping Area: All over the world

- Model: PCDT-1

Specification:-

- Minimum Drop Height: 400mm

- Maximum Drop Height: 2000mm

- Maximum sample Weight: 50 Kg

- Sample Mounting table: 600mm x 600 mm

- Uplift of Mounting Table: Motorized

- Adjustable angle holder is provided with the device.

- Standards: IS:7028 Pt IV

- Type of tests:

- Straight Drop

- Angular Drop

Features:-

- Motorized uplift of test platform

- Drop Height adjustable clamp

- Straight and Angular Drop tests can be performed on a single Instrument

- Strong base plate with rugged structure

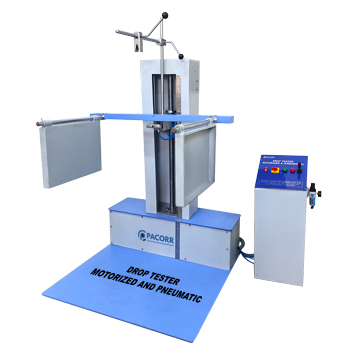

- Optional Features: Pneumatic model and in various platform sizes also available as per requirement.

Understanding the Working Principle of a Drop Tester

A Drop Tester, such as the one offered by Pacorr, operates by subjecting products or packaging to controlled free-fall conditions. The test begins by securing the item at a predetermined height. When initiated, the platform or grip holding the item releases it, allowing gravity to induce a free fall. Upon impact with a solid surface, typically made of steel or concrete, the tester measures the product's response to the impact. Sensors and high-speed cameras often accompany the device to record precise impact data, analyzing points of weakness or damage. This comprehensive testing method provides manufacturers with critical insights into packaging reliability and product durability under realistic conditions.

Top Benefits of Using a Drop Tester

1. Enhanced Product Quality

Using Pacorr's Drop Tester helps manufacturers pinpoint vulnerabilities in packaging and product design. By identifying these weaknesses early, businesses can enhance overall quality, reducing breakage and returns.

2. Cost Efficiency

By preventing product damage through rigorous testing, drop testers significantly lower associated financial losses. Fewer damaged goods result in reduced costs related to replacements, shipping, and customer refunds.

3. Compliance with Standards

Pacorr Drop Testers comply with international testing standards, such as ASTM D5276, ISO 2248, and ISTA guidelines, ensuring products meet global shipping and handling criteria.

4. Improved Brand Reputation

Ensuring products reach customers undamaged enhances consumer trust and brand reliability, leading to better customer satisfaction and loyalty.

5. Risk Reduction

Proactive testing with a drop tester minimizes the risk of shipping-related damage claims and customer complaints, significantly reducing operational risks and improving logistics reliability.

Should You Invest in a Drop Tester?

Investing in a Drop Tester from Pacorr is highly beneficial for businesses involved in manufacturing, packaging, logistics, or e-commerce. Companies that frequently handle fragile or valuable products stand to gain the most from this investment. It not only safeguards your products against unexpected transportation impacts but also elevates your brand's quality assurance standards. If your business prioritizes customer satisfaction, reduced returns, and compliance with international quality benchmarks, integrating a drop tester into your testing procedures is a strategic move.

Final Thoughts on Using a Drop Tester

Incorporating Pacorr's Drop Tester into your quality assurance processes is crucial for ensuring product integrity, minimizing financial losses, and boosting customer satisfaction. Regularly assessing product durability under controlled conditions not only ensures compliance with global standards but also fortifies your market reputation. For businesses serious about maintaining high-quality standards and reducing operational risks, a drop tester is an indispensable asset.

FAQs

Q1. What types of products can be tested using a Drop Tester?

A. Drop testers can be used for a wide variety of products, including electronics, glassware, food packaging, pharmaceuticals, and consumer goods.

Q2. What standards does the Pacorr Drop Tester comply with?

A. Pacorr Drop Testers comply with international standards like ASTM D5276, ISO 2248, and ISTA guidelines.

Q3. How frequently should drop tests be conducted?

A. The frequency of testing depends on product type, packaging design changes, and shipping conditions. Regular testing or after major packaging revisions is recommended.

Q4. Is special training required to operate the Pacorr Drop Tester?

A. Pacorr Drop Testers are designed for ease of use; minimal training is required. Comprehensive user manuals and customer support are provided for smooth operations.

Q5. What is the price range of the Drop Tester from Pacorr?

A. The Drop Tester from Pacorr is priced between INR 60,000 to INR 5,00,000. This range is reflective of various models and configurations designed to meet different testing needs.

Write Your Review

Vishnu

You are using very high quality material for making drop tester and other testing instruments.

Deepak Kumar

My company is satisfied to using Pacorr Drop Tester.

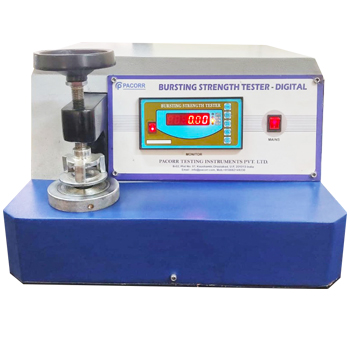

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.