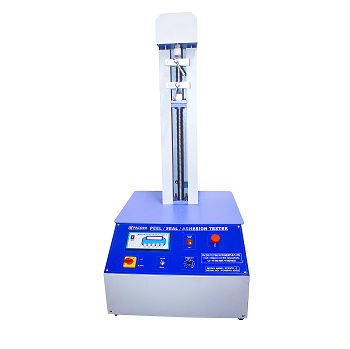

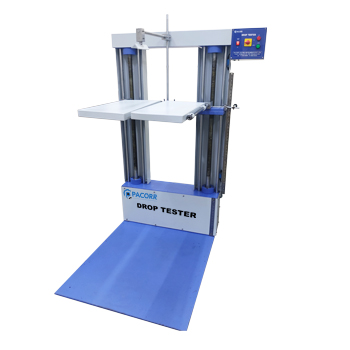

Summary: A Dart Impact Tester is a specialized device used to measure the impact resistance of plastic films and laminated materials by dropping a weighted dart from a specified height onto a test sample. This test, often referred to as the "dart drop test," is critical for determining the ability of plastic films to withstand impact during shipping, handling, and use. It provides vital data on the toughness of materials, helping manufacturers to assess the durability and reliability of their products. The tester helps ensure that packaging materials, such as plastic wraps and protective films, are robust enough to protect contents without tearing or puncturing under normal conditions.

- Shipping Area: All over the world

- Model: PCDIT-1

Specification

- Reference Standard: Machine is Designed According to ASTM D-1709 OR IS 2508.

- Specimen Clamping: Pneumatically Operated Clamps have been used to hold Film.

- Release Mechanism: Electromagnetic Supporting of 2 Kg Weight with a Centering device to Ensure reproducible drop.

- Drop Mechanism: Dart drop mechanism is provide to dart drop at different Drop height.

- Counter: Six digit electronic counters would be provided for counting number of trials.

- Dart Shaft: OD 6.5 mm and 127.5 mm long.

- Dart & Weight: As per Standard Test Method A & B (As per IS 2508)

Features:-

- Designed as per internationally acclaimed standards.

- The test results are accepted pan India and overseas.

- Dart is specifically designed as per standard test methods A & B to perform widely accepted procedures and deliver the best results.

- Equipped with a highly sensitive electromagnetic dart hold area which is responsible to keep the dart unless it dropped for the test. The hold and drop can be controlled by manipulating the electromagnetic power.

- Dart weight is designed to deliver a uniform load on the specimen.

- Strong Pneumatically Operated Clamps ensure a rigid hold of the specimen film.

- Secure shield cover around the specimen holder ensures the safety of the user or the surroundings when the dart free falls over the subject. It resists the dart to fall out of the testing equipment.

- A heavy metal base in the equipment delivers increased stability that is required when a heavy weight is free-falling on a specimen. Any equipment movement can generate errors in evaluation.

- The instrument conforms to the NABL norms and hence provides accurate results.

- The instrument has an inbuilt digital counter that keeps a track of falls performed during a test.

- The drop height can be adjusted as per test requirements.

What is a Dart Impact Tester?

A Dart Impact Tester, also known as a Falling Dart Impact Tester or Drop Dart Impact Tester, is an innovative device designed to assess the impact resistance of materials like plastic films, sheets, and laminated products. By dropping a steel dart from a specified height and measuring the energy required to rupture the material, this tester provides crucial data on the material's resilience to impact.

Dart Impact Tester is high quality and standard-based quality testing equipment that is popularly used in the plastic & films packaging industry to check the quality and evaluate the impact resistance strength of the packaging material. Dart Impact Tester helps to measure the energy which is applied to cause an impact in a sample from a free-falling dart. This can be used to test a wide range of materials, including films, sheets and molded parts.

How It Works

The Dart Impact Tester operates by securing a sample material on the device, followed by dropping a weighted dart from a predetermined height to impact the sample. This process measures the energy required to puncture or break the material, offering insights into its toughness and capacity to endure external stress.

Benefits of Dart Impact Testing

- Safety Assurance: Identifies product weaknesses, enhancing safety and reducing liabilities.

- Product Durability: Ensures products withstand real-world conditions, extending their lifespan.

- Compliance with Standards: Demonstrates adherence to international quality standards.

- Cost Savings: Early detection of vulnerabilities reduces long-term expenses.

Advanced Features

Pacorr's Dart Impact Tester boasts advanced features like portable clamps for secure sample placement, customized weights for varied testing needs, a manual operation mode, an electromagnetic dart hold and release mechanism, adjustable dart heights, and a digital counter for accurate results.

Applications in Industries

This tester is indispensable in packaging, automotive, and construction sectors, ensuring materials like plastic films and laminated sheets meet the required impact resistance levels for safety and durability during transportation and use.

The Dart Impact Tester by Pacorr emerges as a vital tool in the realm of material testing, offering unmatched insights into material durability and impact resistance. Its ability to ensure safety, comply with global standards, and enhance product longevity makes it an indispensable asset across multiple industries. As technology advances, the significance of Dart Impact Testing only grows, promising even more accurate and reliable assessments in the future.

Plastic packaging film is used by a wide variety of packaging industries due to its durable nature, flexibility in stretching and higher impact resistance. As they have maximum use and are utilized by many industries for wrapping up their sensitive products or used in household routines, they tend to experience a lot of wear & tear during their use. The films must be resistant enough to avoid cracks of bursting easily against a sudden impact. The most concerning situation encountered by plastic film manufacturers is a vertical free fall of load taken by the plastic film. Such a scenario can lead to the bursting of films and result in a damaged product.

However, one can avoid such product failure by conducting standard-based quality tests. To evaluate the impact resistance strength the user must perform Falling Dart Impact Test.

The Dart Impact Tester uses a single dart configuration to perform the test. It is a sturdily designed machine that conforms to international testing standards. This ensures that the test results are accepted globally and in a wide spectrum of industries. The specimen holding clamps are adjustable and allow a variety of specimens to get tested. The dart has a defined weight as per test standards. The dart holder works on a pneumatically managed electromagnetic technique. It allows a stronghold of the dart and quick release during the test. The fall height can be adjusted based on the requirements. The counties of tests performed are recorded on a digital counter. The evaluation reports can be used either as a quality monitoring result or for final use comparisons.

- Packaging Material Testing: Assess the impact resistance of packaging materials to safeguard your products during transit and storage.

- Manufacturing Quality Control: Ensure that your manufacturing processes consistently produce materials that meet or exceed performance standards.

- Research and Development: Use precise impact testing to innovate and improve the quality of your materials and products.

- Compliance Testing: Stay compliant with industry-specific regulations and standards to meet customer expectations and legal requirements.

Our Dart Impact Tester represents the culmination of years of research and innovation. By selecting our testing solution, you're investing in a dependable tool that enhances the safety and durability of your products. Our commitment extends beyond the purchase, as we offer exceptional customer support and comprehensive training to maximize the benefits of your investment.

Don't compromise on quality, safety, or performance. Invest in the future of your products with the Dart Impact Tester. Reach out to us today to discover how this indispensable testing equipment can drive your business forward.

FAQ's

Q1. How does a Dart Impact Tester work?

A. A Dart Impact Tester works by evaluating the impact resistance of materials such as plastic films, sheets, and laminated materials. During testing, a weighted dart is released from a specified height onto a securely clamped test specimen. The dart strikes the material, and the energy or weight required to puncture or damage the sample is recorded. This measurement helps determine the material’s ability to withstand impacts, indicating its durability and suitability for real-world applications like packaging and transportation.

Q2. What are the benefits of using a Dart Impact Tester in manufacturing?

A. The Dart Impact Tester offers several benefits, including ensuring product safety by identifying weak points, enhancing product durability to withstand real-world conditions, ensuring compliance with industry standards, and facilitating cost savings by detecting vulnerabilities early in the production process.

Q3. Which industries can benefit from Dart Impact Testing?

A. Dart Impact Testing is crucial for industries involved in manufacturing or using packaging materials, construction materials, and automotive components. It helps these industries to ensure that their products meet required safety and quality standards.

Q4. What standards does the Dart Impact Tester comply with?

A. The Dart Impact Tester complies with various national and international standards, including ASTM D1709, ISO 7765-1, TAPPI T803, EN 12691, and BS 2782-6 Method 621A. These standards provide guidelines for conducting the test, ensuring consistency and reliability of results across different laboratories.

Q5. Can the Dart Impact Tester be used for materials other than plastics?

A. While the Dart Impact Tester is primarily designed for testing the impact resistance of plastic films and laminated materials, it can also be applicable for testing other types of thin materials used in packaging, construction, and automotive industries. However, the specific suitability and setup may vary depending on the material characteristics and testing requirements.

Q6. What is the price range for the Dart Impact Tester from Pacorr?

A. The Dart Impact Tester from Pacorr is priced between INR 65,000 and INR 4,00,000. This range accommodates various configurations and customizations designed to meet specific testing requirements and industry standards. To receive a precise quote tailored to your requirements, please visit pacorr.com or contact Pacorr's customer support directly for comprehensive assistance and information.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.