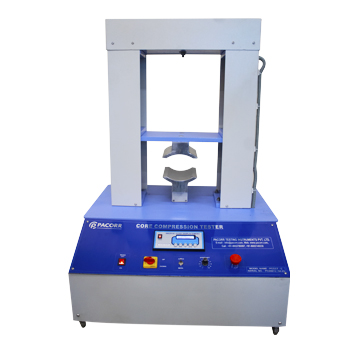

Compression Strength Tester is the renowned testing machine used to test the maximum compressive load that a test specimen can withstand until it deforms or ruptures by a certain percentage. Standard application requires a minimal force whereas for certain heavy applications, higher compression strength is required. To perform the test using a compression tester, the product is placed between two parallel compression plates. Then the uniform amount of compressive load is applied on the sample and the maximum load value at which the sample starts rupturing is recorded by the machine. The testing machine is designed keeping in mind the national and international standard testing methods such as ISO 11093.

- Shipping Area: All over the world

- Model: PCST-30D

Compression strength testing is paramount in determining the durability and resistance of packaging materials against compressive forces during storage and transportation. Pacorr's Compression Strength Tester emerges as a pivotal tool, designed to measure the maximum compressive load a test specimen can endure before undergoing deformation or rupture. This test is vital for ensuring product safety and compliance with industry standards, especially crucial in industries like paper and packaging, where the integrity of corrugated boxes, winding rolls, and other packaging forms is tested.

How Pacorr's Testers Elevate Packaging Standards

Pacorr offers an array of Compression Strength Testers, including the Box Compression Tester, celebrated for its advanced features and reliability. These testers are equipped with cutting-edge technology such as microprocessor-based displays for accurate test results, an electro-pneumatic system for maintenance-free operation, and a rugged structure to withstand rigorous use. Furthermore, they support various testing standards, including ASTM D642 and ASTM D4169, catering to a global audience.

The significance of these testers extends beyond mere compliance. They play a crucial role in product development, allowing manufacturers to design packaging that meets specific strength requirements, thereby enhancing product safety, reducing damage, and fostering customer satisfaction

Why Choose Pacorr?

Pacorr stands out for its commitment to quality and innovation. Their Compression and Box Compression Tester is designed with user-friendly features, such as feather-touch controls and LCD displays with backlit for easy operation and clear readability. These instruments offer versatility and precision, with options for customization to meet the varied needs of the packaging industry.

Maintaining Pacorr's testers is straightforward, requiring only regular greasing, dusting, and protection from moisture to ensure their longevity and reliability.This ease of maintenance, coupled with the ability to customize the testers in terms of capacities and sizes, makes Pacorr a preferred choice for businesses aiming to elevate their packaging quality and efficiency.

Pacorr's Compression Strength Testers provide a dependable solution. With their advanced features, compliance with international standards, and the backing of a company committed to quality and innovation, these testers are indispensable tools. Whether you're in the paper, plastic, or packaging industry, integrating Pacorr's technology into your quality assurance process can transform your approach to packaging, ensuring that your products are protected, compliant, and customer-ready.

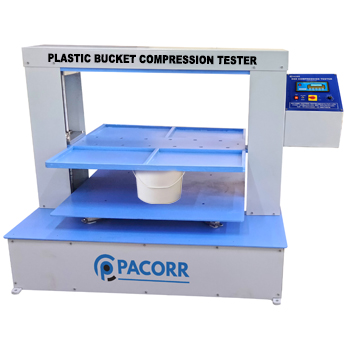

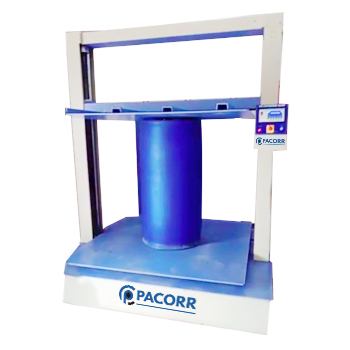

Compression Strength tester is a widely used testing machine which is used in multiple industries to test the compression strength of different types of goods. For instance, it is used in paper and packaging industries to test the compression strength of corrugated boxes, winding roll, in plastic industries to test the strength of bottles and plastic containers, and many more. For determination of crush or compression resistance of these products, the product is placed between two parallel compression plates. Then the uniform amount of compressive load is applied on the sample and the maximum sustained load value is recorded by the machine. The testing machine is designed keeping in mind the national and international standard testing methods such as ISO 11093.

The testing machine comes with:

- Inbuilt calibration facility with electro pneumatic system ensures that it is maintenance-free.

- Once the test is done, it will automatically return to home position.

- It also has a microprocessor-based display that offers precise test results.

- The instrument provides precise results and uniform compression force.

- This also has Tare & Peak load facility.

- It is equipped with a strong base plate with rugged structure.

- It also has feather touch controls that help to operate the machine easily.

| Aspect | Detail |

| Purpose | To measure the maximum compressive load a material can withstand before deformation or rupture. |

| Applications | Widely used in paper, packaging, plastic industries for testing corrugated boxes, plastic bottles, and containers. |

| Features | Microprocessor-based display, precise test results, uniform compression force, electro-pneumatic system, Tare & Peak load facility, rugged structure, and compatibility with various standards like ISO 11093, ASTM D642, ASTM D4169. |

| Importance | Ensures product safety, compliance with industry standards, and quality assurance for packaging. |

| Selection Criteria | Load capacity, platform size, accuracy, manual vs. automated operation, additional features like software integration. |

| Maintenance | Minimal; requires regular greasing, dusting, and moisture protection. |

| Customization | Available in different capacities and sizes to meet specific requirements. |

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.