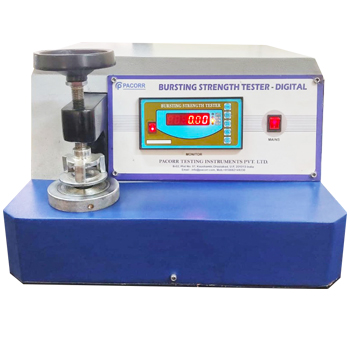

A bursting strength tester quantifies the force needed to burst materials such as paper, cardboard, or textiles, indicating their resistance to puncture and rupture. Bursting Strength Tester is Quality Testing Equipment that is popularly used in the paper and packaging and textile industries. The equipment helps evaluate the Bursting Strength or Bursting Factor Value of a product to determine the capacity of resisting the vertical load before it burst out and damages itself. The tester comes with advanced features and deliverables which are designed as per international standards ensuring high precision in test results.

Availability: In Stock

- Shipping Area: All over the world

- Model: PCBSTD

The Bursting Strength Tester is a paramount instrument in the packaging and material testing industry. It measures the strength required to burst a material, offering critical insights into the durability and resistance of packaging materials against rupture under pressure. This test is crucial for ensuring the reliability and safety of packaging in real-world applications.

Measuring the bursting strength of materials is essential for:

- Assessing material quality and consistency

- Ensuring compliance with international standards

- Enhancing product design by selecting appropriate materials

- Providing data for quality control and improvement efforts

Pacorr's Bursting Strength Tester stands out due to its precision, compliance with international testing standards, and the support it offers users. The instrument is designed for ease of use, ensuring accurate and reliable testing outcomes.

Key Features:

- Digital Precision: Offers accurate measurements and easy readability.

- Versatility: Suitable for a range of materials and applications.

- User-Friendly: Designed for straightforward operation and minimal training requirement.

- Comprehensive Support: Pacorr provides online and offline technical support, along with on-site maintenance and calibration services.

The Bursting Strength Tester is versatile, serving several industries including:

- Packaging: Ensures the integrity and strength of packaging materials.

- Paper: Determines the suitability of paper products for various applications.

- Textile: Assesses fabric strength for quality assurance.

- Polymer and Plastics: Tests the resistance of plastic materials to bursting under stress.

Pacorr's Bursting Strength Tester is an essential instrument for industries requiring rigorous material testing. With its commitment to quality, innovation, and customer service, Pacorr ensures that its clients are equipped with reliable and accurate testing instruments, fostering product excellence and industry compliance.

Material like Paper, Cardboard, Foil, Fabric etc. used in packaging industries must be strong enough to prevent damage under load while in storage or during transportation. They also are responsible to protect the product packed inside. Hence, for Industries like paper & packaging, or textile, ensuring the bursting strength of the raw material is vital to ensure that the material is good enough to sustain through the storage and transit course. The higher the bursting strength, the more resistant is the material against vertical load.

Bursting Strength Tester is highly-précised testing equipment that helps manufacturing industries to evaluate the performance of the material under bursting force. It helps recreate the real-life load exposure to check the sustainable quality of a material.

The tester comes with a Digital Display that helps users to set Testing parameters like time, force applied and the value can be evaluated from the display itself. It’s equipped with two sturdy and strong-built clamps, upper and lower. The lower clamp holds the specimen strong and ensures that the product doesn’t slip off during the test especially when the material is pushed. The upper clamp is built to exert vertical load on the specimen. Once the peak force is achieved in the test where the product fails to resist the load further and burst, the force is automatically recorded and displayed on the screen. The machine also comes with safety switches that assure if at any moment if anything goes wrong in the test, the user can immediately halt the test. The entire machine is built as per the globally recognized standards ASTM D3786, ASTM D774. The material tested and approved utilizing such equipment are accepted worldwide for manufacturing use.

Bursting factor = bursting strength / Grammage

Bursting Strength Tester price from Pacorr is competitively set, offering a high-quality solution designed to measure the bursting strength of materials like paper, cardboard, and corrugated boxes. This robust and precise instrument is essential for ensuring the durability and reliability of packaging materials. Investing in Pacorr's Bursting Strength Tester ensures that businesses maintain high standards in their packaging processes.

Applications:

- Paper boards

- Corrugated boards and boxes

- Industrial fabric and solid fiber boards

- Filter cloth

- Plastic films

- Foils

- Sheets

| Aspect | Details |

| Product Focus | Bursting Strength Tester |

| Industries Served | Paper & Packaging, Plastic & Polymer, PET Bottle & Preform, Poly Films & Laminates, Paint & Coatings |

| Compliance | Strict adherence to International Standards |

| Manufacturer | Pacorr Testing Instruments Pvt. Ltd. |

| Key Features | High precision, user-friendly, comprehensive support |

| Ideal For | Quality assurance in product durability and strength testing |

FAQ's

Q1. What is a Bursting Strength Tester?

A. A Bursting Strength Tester is a specialized machine designed to evaluate the bursting strength of materials such as paper, cardboard, and other similar substrates. The tester operates by applying hydraulic pressure to a defined area of the material until it ruptures or bursts. The pressure required to cause this rupture is measured and used to determine the material's bursting strength. This information is crucial for manufacturers and suppliers, as it helps ensure that their products meet the necessary strength and quality standards for various applications, including packaging and printing. By determining the bursting strength, manufacturers can assess the durability and performance of their materials under stress, which is essential for maintaining product integrity during handling, transportation, and usage. The bursting strength is a key factor in determining the suitability of materials for specific uses, ensuring they can withstand the physical demands of their intended applications.

Q2. What if the diaphragm of the device bursts during testing?

A. If the diaphragm of the bursting strength tester bursts or becomes damaged during testing, it is crucial to replace it immediately to ensure the accuracy and reliability of future tests. The diaphragm plays a vital role in maintaining the pressure applied to the specimen, and any damage can compromise the test results. In such cases, you should contact Pacorr's support team right away. Pacorr provides prompt and efficient customer service, ensuring that the diaphragm is replaced swiftly and professionally. Their support team is well-equipped to handle such issues and will assist in getting the device back to optimal working condition in no time. Regular maintenance and timely replacement of worn-out components are essential for the consistent performance of the tester. By addressing any damage promptly, you can ensure that your testing processes remain accurate and that the integrity of your material evaluations is maintained.

Q3. Which liquid is used for applying hydraulic pressure during the Mullen Test?

A. In the bursting strength tester offered by Pacorr, lab-grade glycerin is used to apply hydraulic pressure on the specimen during the testing procedure, commonly known as the Mullen Test. Glycerin is recommended because it provides better accuracy and consistency in the test results compared to other liquids. Its viscosity and stability ensure that the pressure applied is uniform and controlled, leading to precise measurements of the material's bursting strength. While water can also be used as a hydraulic fluid in this tester, it is not as effective as glycerin in delivering consistent pressure, which may affect the accuracy of the results. Therefore, for optimal performance and reliable data, lab-grade glycerin is preferred. This choice of hydraulic fluid ensures that the bursting strength tester functions efficiently and produces the most accurate and reliable measurements, essential for evaluating the quality and durability of paper, cardboard, and other similar materials.

Q4. Can Bursting Strength Tester be used for testing Plastic materials?

A. No, a Bursting Strength Tester is not suitable for testing plastic materials. This instrument is specifically designed to measure the bursting strength of paper and paper-like materials, such as cardboard and corrugated sheets, which have minimal elasticity. The testing mechanism of the Bursting Strength Tester involves applying uniform pressure until the material bursts, making it ideal for materials that respond predictably under such stress. Plastics, however, possess significant elastic properties that cause them to deform and stretch rather than burst under pressure. These characteristics make plastics difficult to test accurately with a Bursting Strength Tester, as the device is not calibrated to handle the elastic deformation typical of plastic materials. For accurate testing of plastic materials, other specialized instruments are required that can assess their unique properties, such as tensile strength testers or impact resistance testers. Therefore, while the Bursting Strength Tester excels in evaluating the durability of paper-based materials, it is not appropriate for plastics.

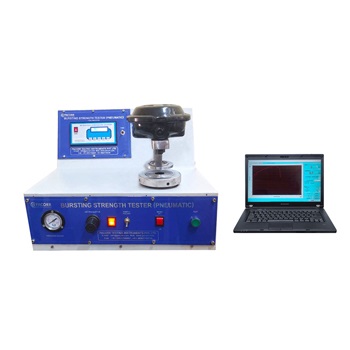

Q5. Is bursting strength tester instrument computerized?

Yes, the Bursting Strength Tester is available in computerized versions, among other models. Pacorr offers three different models of the Bursting Strength Tester: the Digital model, and the Digital cum Computerized model and computerized with pneumatic . The computerized model is particularly advanced, featuring connectivity options that allow users to interface the instrument with a computer. This connectivity enables the downloading of testing data directly to a computer, facilitating better data analysis, storage, and reporting. With the computerized model, users can benefit from enhanced accuracy and efficiency in their testing processes. The ability to digitally record and analyze test results ensures that detailed and comprehensive evaluations of material strength are possible, leading to improved quality control and material performance assessments. Whether you need basic functionality or advanced computerized capabilities, Pacorr's range of Bursting Strength Testers provides the flexibility to meet various testing needs and ensures precise and reliable results.

Q6. What Materials can be tested with bursting strength tester?

A. A Bursting Strength Tester is a versatile instrument used for testing the durability and strength of a wide range of materials. This device is particularly essential in the packaging industry, where it is used to assess the bursting strength of various packaging materials to ensure they can withstand the pressures they will encounter during use. Materials commonly tested with this instrument include paper, corrugated sheets, cardboard sheets, multilayered corrugated sheets, and fabrics. By determining the bursting strength, manufacturers can evaluate the quality and durability of these materials, ensuring that they meet the necessary standards for protecting goods during transportation and storage. The Bursting Strength Tester works by applying uniform pressure to a sample until it bursts, measuring the force required to achieve this. This data is crucial for quality control and helps in the development of more robust and reliable packaging solutions. Whether for simple paper products or complex multilayered sheets, the tester provides valuable insights into material performance under stress.

Q7. What is the price range for a Bursting Strength Tester?

A. The price range for a Bursting Strength Tester typically falls between 50,000 to 2,50,000 INR, depending on the features and specific model. This equipment is essential for evaluating the strength and performance of various materials under pressure, making it crucial for industries such as textile, paper, and packaging. To get precise pricing and select the right model for your application, it's advisable to contact Pacorr directly.

Write Your Review

Harish

Getting best results. Thanks

Lakhwinder

Thank you for Best machine

S.S Jha

Machine quality is the best.

Nilesh

Getting Accurate results.

Sunil Kumar

you always deliver work ahead of schedule and never forget any details

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.