Summary - A Box Compression Tester is an advanced instrument designed to evaluate the compressive strength and durability of boxes and various packaging materials. This testing machine systematically applies controlled compressive pressure on samples, usually corrugated boxes, until they deform or fail. Essential features include digital control panels for precise force adjustments, customizable testing speeds, and real-time data monitoring, enabling accurate and reliable analysis. Predominantly utilized in packaging, logistics, shipping, and manufacturing sectors, box compression testers help guarantee that packaging materials can endure stacking pressure and rough handling during storage and transportation. Consequently, using this equipment helps businesses prevent product damage, reduce losses, and uphold high safety and quality standards.

Availability: In Stock

- Shipping Area: All over the world

- Model: PCBCTD

What is a Box Compression Tester?

A box compression tester is a precision instrument used to determine the compressive strength of a single packaging box under applied pressure. By simulating stacking conditions during storage or transportation, the tester evaluates how much weight a box can handle before it begins to deform or collapse. This data is essential for packaging design, helping manufacturers ensure that a product remains secure throughout the supply chain.

The device applies a controlled vertical load to a test sample, recording the maximum force the box can endure. Often used in industries that rely on corrugated or cardboard packaging, a box compression tester supports quality control by verifying if packaging meets durability standards. With accurate measurements, it helps prevent product damage, optimize material use, and reduce costs related to packaging failure.

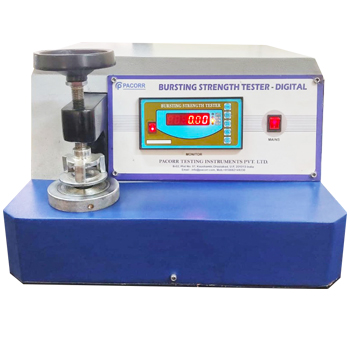

A box compression tester assesses the structural integrity of cardboard boxes by applying pressure until they deform. This test is crucial for understanding how boxes will perform under stacked conditions. Box Compression Tester (Digital Model) is used to evaluate the performance quality of packaging boxes. It calculates the amount of vertical compressive force a particular cardboard box can take before collapsing or deformation. The testing machine is specifically designed as per international standards and comes with advanced features making the analysis precise and easier to conduct.

Corrugated or Non-Corrugated Cardboard Boxes are the most popularly used in the packaging and delivery industry. While they are stored and transported, they are subjected to a lot of vertical loads, frictional forces that may damage the integrity of the boxes or cause a deflection which can further damage the products inside. This is why it’s is vital to evaluate the strength of the cardboard boxes before they are used in the market. The Box Compression Tester (BCT) is a high standard based and precisely designed equipment that can recreate the storage or transportation scenario and exert calculative compression load. It helps in studying the impact of the compression strength on the boxes and the maximum amount of force that a box can bear before deflection. These test values can help the user understand the quality category of material and also their client can decide on the number which box type to opt for packaging or delivery of which product.

The Equipment comes with a moving compression plate which is equipped with load cells that ensure that the compressive load spreads uniformly to the specimen surface. This way we can ensure accuracy in results. A rigid platform for placing a wide variety of specimen sizes for the test. The tester has a digital display that helps in taking quick test readings of the force applied as well as the deflection amount of the specimen. Equipped with advanced and user-friendly features like an auto-cut off facility that stops the machine once there is a deflection sensed in the testing specimen. The instrument also has the peak hold feature and can record up to ten top testing results which are helpful for future reference and analysis. The machine body has a powder coating that makes it fit for long-run use even in the harshest working environments. The box compression tester comes with different platform sizes for testing sizes of containers. The equipment is specifically designed as per international standards like ASTM D642, ASTM D4169, ISO 2234:2015 and EN ISO 12048.

Box Compression Testing is a crucial process in the packaging industry, ensuring the durability and strength of boxes to prevent damage during storage and transportation. Pacorr's Box Compression Tester is an advanced tool designed to evaluate the performance quality of packaging boxes, calculating the amount of vertical compressive force a box can endure before collapsing or deformation.

Why Box Compression Testing is Vital

- Industry Standards Compliance: Ensures packaging meets industry standards and regulations.

- Product Safety: Improves product safety by testing the compression resistance of packaging materials.

- Quality Assurance: Helps in determining the resistance strength of a packaging box to deformation and stability during stacking.

Selecting the Right Box Compression Tester

When choosing a Box Compression Tester, consider the following:

- Load Capacity: Ensure the tester can handle the typical weight range of your packaging plus a margin for safety.

- Platform Size: Select a tester with a platform that accommodates the boxes you use, ensuring versatility in testing different sizes.

- Accuracy: Look for testers with precise force measurement capabilities, typically featuring a digital display for reliable results.

- Manual vs. Automated: Decide based on your operational needs; automated testers provide efficiency but at a higher cost.

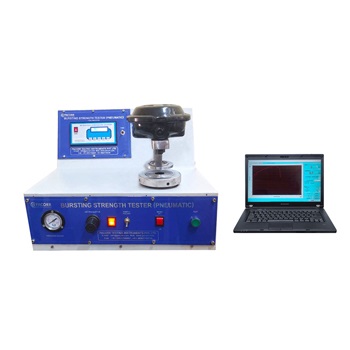

- Additional Features: Advanced testers may offer software integration for data analysis, enhancing the testing process.

Pacorr offers a wide range of Box Compression Testers, including manual and automated models, with various capacities and customizable options to meet specific testing requirements.

Maintaining Your Box Compression Tester

Pacorr's Box Compression Testers are designed with high-quality materials requiring minimal maintenance. Regular greasing of the lead screw, keeping the machine dust-free, and protecting it from moisture will ensure its longevity and reliability.

Box Compression Tester is essential for the packaging industry, ensuring that products are protected during transportation and storage. Pacorr's Box Compression Tester is designed to meet global standards, providing accurate, reliable testing for a wide range of packaging materials. By selecting the right model and following proper maintenance practices, businesses can significantly improve their packaging quality, ensuring product safety and customer satisfaction.

It can customized as per requirement

Specifications:-

- Capacities: 500Kgf, 1000Kgf, 2000Kgf & 3000Kgf

- Display: LCD (Digital) with Backlit

- Accuracy: ± 1% of FSD.

- Least Count: 50gm to 500gm

- Test Platform Size : 600mm x 600mm, 800mm x 800mm, 1000mm x 1000mm & 1000mm x 1200mm

- Test Speed: 12.5 ± 2.5 mm/min

- Speed Drive: 10mm/min to 50mm/min.

- Load Sensors: 4 Nos.

- Paint: Powder Coated

- Motor: Crompton/ Bharat Bijlee make Induction Motor (1hp/1.5hp/2hp, as per the machine capacity) & Drive

- Power: 220V AC, Single phase, 50 Hz

- Standard: ASTM D642, ASTM D4169

- Options: Computerized Model Available

Features:-

- Advance electronics for accurate test results

- 4 Load sensor based highly accurate machine

- Tare and Peak Hold Facility is provided

- Speed Drive 10mm/min to 40mm/min. provided

- Over travel protection

- Over load protection

- Very Strong, Heavy duty and rugged structure

- Digital LCD display with backlit

- Available in various platform sizes and Load Cell Capacity.

FAQ's

Q1. Why is box compression strength testing important for packaging?

A. Box compression strength testing plays a crucial role in ensuring that a single package can endure vertical pressure during stacking, shipping, and storage. By accurately measuring how much weight a box can withstand before collapsing, the test helps prevent product damage, minimize waste, and improve overall packaging reliability. This kind of testing is especially important for goods transported over long distances or stored in high-volume warehouses.

Q2. Is this machine is available in customized sizes and capacities?

A. Yes, Pacorr offers the Box Compression Tester in various capacities and sizes to meet diverse customer requirements. Understanding that different industries and applications have unique needs, we provide customization options for our machines. Customers can request specific sizes and capacities to ensure the tester perfectly fits their testing requirements. Whether you need a machine for small packaging boxes or larger containers, our team can tailor the Box Compression Tester to your precise specifications. This flexibility ensures that you receive a testing instrument that not only meets but exceeds your expectations in terms of functionality and performance. Our commitment to customization allows us to provide solutions that cater to the specific demands of our clients, enhancing the accuracy and efficiency of their testing processes. For customized orders, please contact our customer support team, who will assist you in selecting and configuring the ideal machine for your needs.

Q3. My machine is giving incorrect testing results when I compare to the other testing machines. What should I do?

A. If your machine is producing incorrect testing results compared to other testing machines, it is likely that your device needs recalibration. Calibration is crucial to ensure the accuracy and reliability of test results. Over time, factors such as regular use, environmental conditions, and mechanical wear can cause the machine to drift from its calibrated settings. To address this issue, you should contact our customer support team for assistance. They can provide detailed guidance on the recalibration process or arrange for a professional recalibration service. Our support team is equipped with the expertise to diagnose calibration issues and ensure that your machine is restored to its optimal performance. Regular recalibration and maintenance are essential to maintain the precision of your testing equipment, ensuring consistent and reliable results for your material testing needs. Do not hesitate to reach out for support to keep your machine functioning accurately.

Q4. What should I do for maintenance of the machine?

A. Maintaining your Pacorr testing machine is crucial for ensuring its longevity and optimal performance. Although these machines are manufactured using high-grade materials that require minimal maintenance, regular upkeep is essential. Key maintenance tasks include greasing the lead screw periodically to ensure smooth operation and prevent wear and tear. Additionally, keeping the machine dust-free is vital, as accumulated dust can interfere with its mechanical components and affect accuracy. It's also important to protect the machine from moisture, which can lead to corrosion and damage electronic parts. Regularly inspect the machine for any signs of wear or damage and address them promptly. By following these simple maintenance steps, you can ensure that your Pacorr machine remains in excellent working condition, providing reliable and accurate results over its lifespan. Should you need further guidance on maintenance, our customer support team is always available to assist you with detailed instructions and professional advice.

Q5. My testing device does not reset when I restart the test. What should I do?

A. If your testing device does not reset when you attempt to restart a test, there are a few steps you can take to resolve the issue. First, try pressing the TARE button on the digital display. This button is designed to reset the display, clearing any previous readings and allowing you to start the test anew. If pressing the TARE button does not resolve the problem, the issue may require further troubleshooting. In such cases, it is advisable to contact our customer support team for assistance. Our support team is equipped with the expertise to help diagnose and resolve technical issues with your device. They can provide guidance on additional troubleshooting steps or arrange for professional servicing if necessary. Ensuring your device is functioning correctly is essential for obtaining accurate and reliable test results, so do not hesitate to reach out for support if needed.

Q6. What types of packaging containers can be tested using Box Compression Tester?

A. The Box Compression Tester is a versatile and comprehensive testing instrument designed to evaluate the strength and durability of various packaging containers. It is specifically used to test the compressive strength of containers such as cardboard boxes, corrugated boxes, and other similar packaging materials. This tester measures the ability of these containers to withstand compressive forces during storage, stacking, and transportation. By applying uniform pressure until the container deforms or collapses, the Box Compression Tester provides valuable data on the maximum load the container can bear without compromising its structural integrity. This information is crucial for manufacturers and suppliers in the packaging industry to ensure their products meet quality and safety standards. Testing with the Box Compression Tester helps in optimizing packaging designs and materials, ensuring that the containers can protect their contents effectively throughout the supply chain, from production to end-user delivery.

Q7. How much does a Box Compression Tester price?

A. The price of a Box Compression Tester varies based on the model and specifications. Typically, the cost ranges from 1,20,000 to 5,50,000 INR. For accurate pricing and to choose a model that fits your testing requirements, it's recommended to contact Pacorr directly or visit their website.

Write Your Review

Anand Mishra

Box Compression Tester is working fine and thanks for online installation.

Alok

Thanks for the heavy quality box compression tester.

Manish

Received best quality box compression testing machine.

Mithlesh Kumar

I recommend others to have business with Pacorr Testing Instruments.

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.