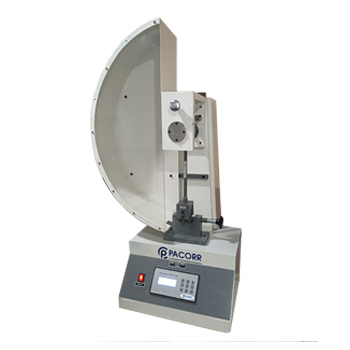

Melt Flow Index (MFI) Tester (Computerized) is an advanced version in the Melt Flow Index testing equipment range. The equipment is used for performing Melt Flow Index Test that helps evaluate the quality standards in the polymer industry. The machine is supported with computerized processes and provides automated evaluation.

Availability: In Stock

- Shipping Area: All over the world

- Model: PCAMFIC-1

What is a Melt Flow Index Tester?

A melt flow index tester is a precision instrument used to measure the flow rate of a thermoplastic material when it is melted under specific conditions. By applying heat and pressure to a single polymer sample, the tester determines how easily the material flows through a narrow die, providing critical data on its viscosity and processing behavior. This measurement helps manufacturers assess the suitability of a material for molding, extrusion, or other production methods.

With a melt flow index tester, a quality control technician can quickly identify whether a plastic batch meets production standards. The device typically includes a heated barrel, a piston for applying force, and a die to control material output. This test plays a key role in ensuring consistent material performance, especially in industries where precision and reliability are non-negotiable.

Melt Flow Index Tester is one of the major testing protocols followed in the polymer industry. The MFI test is considered to be a mandatory criterion to clear for products before they can be selected ahead of production. The MFI value determines the molecular weight of the polymer and helps the manufacturer to assess the melting behaviour of plastic material.

The MFI test is a procedure in which a polymer sample is placed inside the tester, heated at a standard set temperature. The molten plastic is then pushed through a standardized die with a specified diameter by exerting a fixed amount of weight. The molten plastic which comes out within 10 min of time is evaluated. This value is the Melt Flow Index. Lower The MFI value, Higher is its Flexible nature. The same procedure when performed on multiple samples helps the manufactures to categorise as per the quality and can easily decide its further use.

The melt flow index tester (MFI) comes with automated services like automated sample cutting which ensures that when the fixed time of 10 min completes the melted sample is automatically cut off and the test procedure stops. Once the procedure ends the user no need to weigh the material separately as the equipment deliver an automated weighing service too with an in-built digital weighing balance. The High-end MFI tester also brings an auto MFR Calculator. Hence, the user is free from manual cutting, weighing and evaluating the test results.

The equipment has an inbuilt window based software and RS 232 port that can connect your equipment to your computer. With a simple installation of the software, the user can get the test analysis reports on their system. With the help of computer connectivity, it becomes very easy to analyze and generate test reports. It is also equipped with precision-based features like Microprocessor-based temperature control that ensure higher accuracy of temperature maintained during the test.

The Melt Flow Index Tester (MFI) is designed as per globally acclaimed standards like ASTM D 1238-1992 and ISO 1133.

Specification:-

- Display: Digital LCD with backlit

- Auto Cutting

- Auto Weighing

- Inbuilt digital Weighing Balance with Accuracy of 0.001gm (1mg).

- Auto MFR Calculation.

- Window based software.

- RS 232 port to Interface with Computer.

- Temp Controller: Microcontroller based LED Temperature Controller.

- Temperature Range: Upto 400ºC

- Resolution: 0.1 degree C

- Accuracy: ± 0.1°C.

- Timer: Range up to 999.9 Seconds

- Weights: 2.16Kg & 5.0 Kg hard chrome plated weights.

- Accessories: Orifice, Piston, Material charger, Barrel cleaner, Orifice cleaner, Sample Cutter.

- On completion of test scrolling display for all the Individual results and Average MFI value.

- Transfer to PC or Computer for record or Print on completion of Test.

- Power: 220V AC / 50 Hz, Single Phase

- Amperes: 4 Amps.

- Table Top Model

Note: In addition to this we request you to buy Personal Computer with CD Rom & Serial interface COM Port (COM1).

Features:-

- Paint: Powder Coated.

- Computer/Laptop: Client scope

FAQ's

Q1. What is a Melt Flow Index (MFI)Tester and why is it important in quality control?

Answer: A Melt Flow Index Tester measures the rate at which a thermoplastic polymer melts under specified conditions of temperature and pressure. This test is crucial for manufacturers because it helps determine the material's flow characteristics, ensuring consistency in production and confirming compliance with international quality standards. By using this tester, companies can better predict how the polymer will behave during processing, leading to higher quality products.

Q2. How does the Melt Flow Index Tester contribute to material research and development?

Answer: In material research and development, the Melt Flow Index Tester provides essential data that helps in modifying polymer properties according to specific application needs. It allows researchers to experiment with different additives and processing conditions to achieve desired material characteristics such as strength, flexibility, and durability. This tool is indispensable for innovating new polymer blends and enhancing existing ones to meet evolving market demands.

Q3. What are the key features to look for in a Melt Flow Index Tester?

Answer: Key features to consider include precision temperature control, user-friendly interface, and automated data logging capabilities. Precision temperature control ensures accurate test conditions, while a user-friendly interface simplifies the operation for technicians. Automated data logging is vital for maintaining consistent records and analyzing trends over time, which is beneficial for ongoing quality assurance and regulatory compliance.

Q4. Can the Melt Flow Index Tester be used for all types of thermoplastics?

Answer: Yes, the Melt Flow Index Tester is versatile and can be used for a wide range of thermoplastic polymers, from highly rigid materials like polycarbonate to softer forms like polyethylene. However, the specific setup and parameters might vary depending on the polymer’s characteristics, so it's essential to consult the tester's manual and adhere to industry-specific testing guidelines.

Q5. How does regular use of the Melt Flow Index Tester impact production efficiency?

Answer: Regular use of the Melt Flow Index Tester helps maintain the consistency of the plastic materials used in production, which reduces the risk of defects and enhances overall product quality. Efficient testing routines allow for quick adjustments in the production process, minimizing downtime and material wastage. Consequently, this leads to more streamlined operations and a significant improvement in production efficiency.

Q6. What is the price range for a Melt Flow Index (MFI) Tester?

A. The price of a Melt Flow Index Tester can vary depending on the specific model and its features. Generally, the cost ranges from approximately 50,000 to 3,00,000 INR. For precise pricing details and to select the right model for your needs, contacting Pacorr directly or visiting their website is advised.

Write Your Review

Santosh Kumar

High Quality product

Sohan

Product Working Fine.

Kishan

Fiber body is very strong.

Test By Developer

Okay. Teasted

Related Products

Our Clients

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.