Poly Films and Laminates Testing Instruments

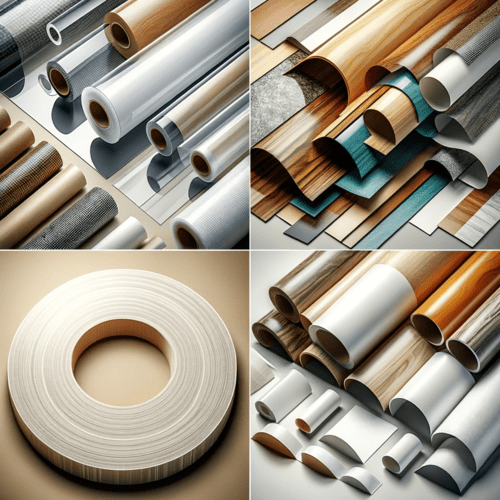

Poly Films and Laminates are the most popular products used in the packaging industry. The material has benefits like flexibility, elongation, better tensile strength and maximum resistance against extreme conditions. Such products are renowned and are in high demand in several industries. With higher competition in the market, manufacturers must deliver high-quality. To ensure that, they must test every aspect of their product.

Poly films must be resistant to maximum situations such as extreme weathering conditions and transportation or storage impact, like vertical load, extreme heat, dry heat, a sudden impact and much more.

What type of material can be tested by Poly Films and Laminates Testing equipment?

Material like poly films and laminates are used in several verticals like packaging, flexible packaging, polythene bags. They are not only used in domestic uses but also used in superior verticals like automotive industries, aerospace etc. They are made tough and must be tested for their end-use standards. The requirements of properties can vary from sector to sector.

Which type of factors or properties the Poly Films and Laminates Testing machines can evaluate?

Our range of Poly Films and Laminates Testing machines allows evaluation of Adhesion Strength, Peeling Strength, resistance against free-falling dart, seal quality, coefficient of friction, rubbing resistance strength, scuff strength, colour quality, specific gravity, vacuum leaks, wall thickness, colour uniformity and resistance to dry heat. Our range delivers a comprehensive testing instrument that delivers complete testing of poly and laminate products.

What kind of test equipment is available?

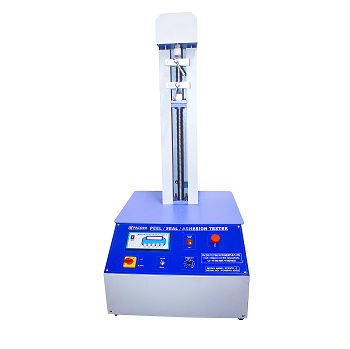

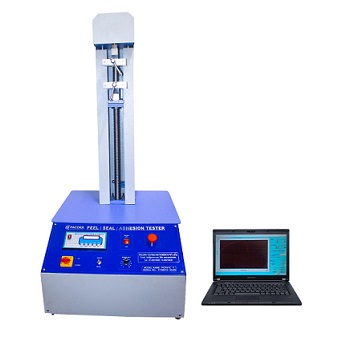

- Peel / Seal / Bond and Adhesion Strength Tester - Digital - Test the adhesion strength between packaging seals or peel-off labels. It comes in a high-tech computerized version. They can check the seal adhesion between two material surfaces stuck together.

- Dart Impact Tester - Test the sudden impact of free fall dart on poly films. It also comes in Touch Screen (HMI based). The free-falling dart can help the manufacturer predict the level of damage its products can have under such situations.

- Laboratory Heat Sealer - To check the seal quality of packaging under heating conditions. With increasing heat levels many seal adhesives don't work, the machine helps test the performances of distinct adhesion products.

- Coefficient of Friction Tester- Testing the coefficient of friction value of plastic films and comes in Computerised -(Static & Kinetic)The machine helps evaluate the impact of friction and see how well a product may repel the frictional forces.

- Rub Resistance Tester - It evaluates the resistance strength against rubbing forces. This helps in evaluating the retaining strength of the poly material under constant rubbing forces.

- Scuff Resistance Tester - The tester evaluates the resistance against the scuffing forces.

- Precision Colorimeter - for inspection of colour quality on plastic surfaces.

- Specific Gravity Balance - For checking the specific gravity balance of poly film material

- Vacuum Leak Tester-Digital & Deluxe - that allows the testing of vacuum leaks in packages. The tester can detect even microsized leaks or holes in the packages which otherwise remain unnoticed.

- Digital Thickness Gauge - Measures poly films or laminates’ wall thickness. This equipment helps to measure the structural properties as well.

- Colour Matching Cabinet - To ensure that the colour of the product appears the same under different lighting conditions. It ensures that the product is acceptable in all nations which may have different lighting conditions

- Laboratory Hot Air Oven - To check the resistance against the dry heat impact. The oven allows dry heat under which the product performance can be checked.

Our complete range of poly and laminates testing instruments bring high-end testing and deliver high accuracy as they all are designed as per international testing standards and their test results are accepted worldwide.

Pacorr stands as a beacon in the field of testing instruments, focusing on delivering precise and highly functional testing equipment for various materials, including poly films and laminates. This article delves into the significance of such instruments, elucidating their critical role in quality assurance and compliance within the relevant industries.

In the realm of packaging, automotive, and chemical industries, the quality and reliability of poly films and laminates are paramount. These materials must not only meet aesthetic and functional requirements but also comply with rigorous industry standards. Pacorr, through its extensive range of testing instruments, enables businesses to achieve and maintain the highest quality standards.

Importance of Poly Films and Laminates Testing

Testing poly films and laminates is critical for several reasons:

- Quality Assurance: Ensures the materials meet the desired standards in terms of strength, durability, and appearance.

- Regulatory Compliance: Helps manufacturers adhere to international quality and safety standards.

- Performance Evaluation: Assesses how the materials behave under various conditions, including extreme temperatures and physical stress.

Choosing the Right Testing Instruments

Selecting appropriate testing instruments is vital for achieving accurate and reliable results. Factors to consider include the specific requirements of the industry, the materials being tested, and the desired testing parameters. Pacorr's expertise and wide product range ensure that businesses can find the perfect match for their testing needs.

Pacorr's dedication to precision and excellence is evident in its range of testing instruments for poly films and laminates. By providing tools that measure critical parameters such as structural integrity, chemical composition, and environmental resistance, Pacorr empowers industries to uphold the highest quality standards, ensuring product reliability and customer satisfaction.

| Aspect | Details |

| Focus | Testing Instruments for Poly Films and Laminates |

| Manufacturer & Supplier | Pacorr Testing Instruments Pvt. Ltd. |

| Target Industries | Packaging, Automotive, Chemical, Flexible Packaging |

| Key Testing Parameters | Structural thickness, Dimension, Impact of free fall load, Behavior in extreme weather conditions, Chemical composition, Carbon content, Melt flow rate |

| Highlighted Instruments | Melt Flow Index Tester, Tensile Testing Machine, Humidity Chamber, Stability Chamber, Gloss Meter |

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)

.jpg)