Plastic & Polymer Testing Instruments

Plastic and polymer materials have become integral to a wide range of industries due to their versatility, durability, and cost-effectiveness. However, ensuring the quality, performance, and safety of these materials is crucial for manufacturers to maintain compliance with industry standards and meet customer expectations. At Pacorr, we specialize in offering advanced plastic and polymer testing instruments designed to help manufacturers assess the mechanical, thermal, and chemical properties of these materials with precision and reliability.

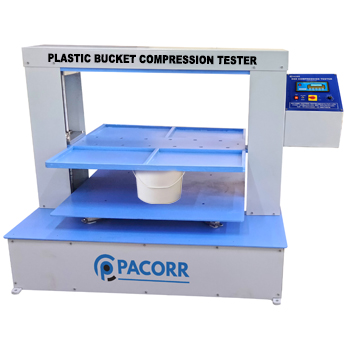

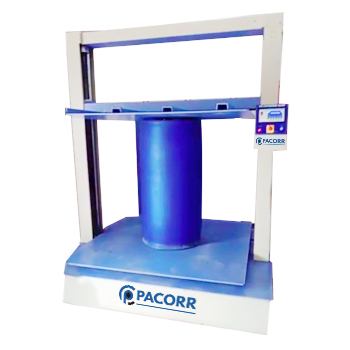

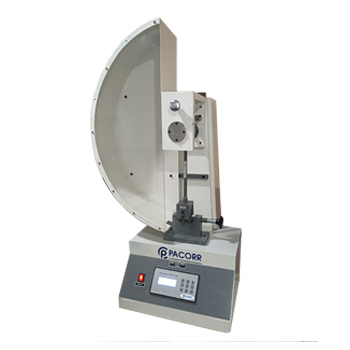

Our cutting-edge testing instruments are crafted to perform a wide array of tests, such as tensile strength, impact resistance, elongation, and thermal stability. These tests enable manufacturers to evaluate the material's performance under different conditions and ensure its suitability for specific applications. Whether in automotive, packaging, construction, or consumer goods, accurate testing of plastic and polymer products minimizes defects, reduces waste, and enhances product longevity.

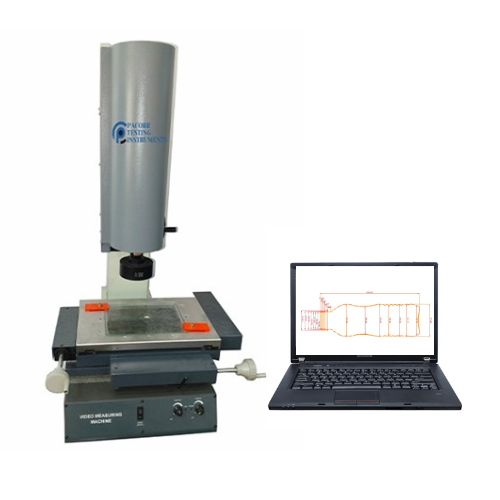

Pacorr's instruments are developed using advanced technology and robust materials, ensuring long-term accuracy and efficiency. Our portfolio includes devices for melt flow index testing, which determines the flow properties of thermoplastics, and environmental stress crack resistance (ESCR) testers that assess a material's ability to withstand cracking under stress. Additionally, we provide cutting-edge solutions for analyzing color, gloss, and opacity, essential for maintaining aesthetic and functional consistency in end products.

With a focus on user-friendly operation, Pacorr’s instruments are engineered to deliver precise results while being easy to use and maintain. Our products adhere to international testing standards such as ASTM, ISO, and DIN, ensuring that your products meet global compliance requirements.

By choosing Pacorr’s plastic and polymer testing instruments, manufacturers can confidently validate the quality of their materials, streamline production processes, and enhance customer satisfaction. Trust Pacorr to be your partner in delivering superior quality and performance in every product you create.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)

.jpg)