Paint, Plating & Automotive Testing Instruments

A paint, plating & automotive testing instrument is an indispensable solution for industries that demand high-quality finishes, coatings, and materials in their products. From automotive manufacturers to industrial equipment producers, the need for accurate testing to ensure durability, aesthetics, and functional performance has never been greater. These instruments empower manufacturers to meet stringent industry standards while delivering products that excel in performance and appeal.

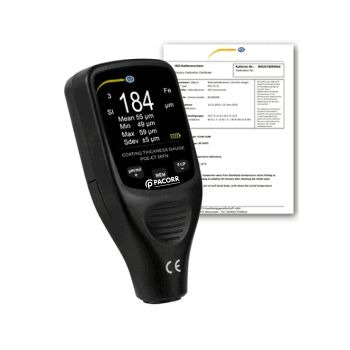

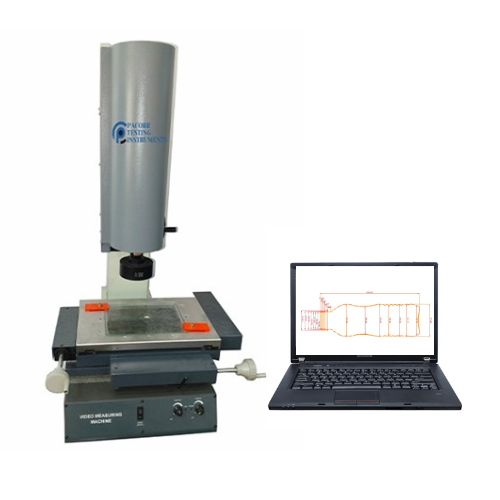

Paint and coating applications require comprehensive evaluation to ensure they withstand environmental factors like humidity, UV radiation, temperature fluctuations, and mechanical wear. A paint, plating & automotive testing instrument provides precise measurements of key properties such as adhesion, thickness, gloss, color consistency, and impact resistance. By testing these attributes, manufacturers can ensure their coatings maintain integrity and functionality over time.

Plating plays a vital role in enhancing the durability and corrosion resistance of materials, particularly in automotive and industrial applications. Testing instruments assess the uniformity, hardness, and corrosion resistance of plating to verify its performance in harsh environments. These tests are essential to ensure the plated surfaces protect components effectively and extend their operational life.

With advanced features like automated testing, real-time data analysis, and user-friendly interfaces, modern paint, plating & automotive testing instruments simplify the quality control process while delivering accurate and repeatable results. Investing in these instruments allows manufacturers to reduce defects, optimize production, and gain a competitive edge in their markets.

By integrating paint, plating & automotive testing instruments into your quality assurance process, you can enhance product quality, ensure compliance with industry standards, and maintain customer trust, helping your brand achieve long-term success.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)