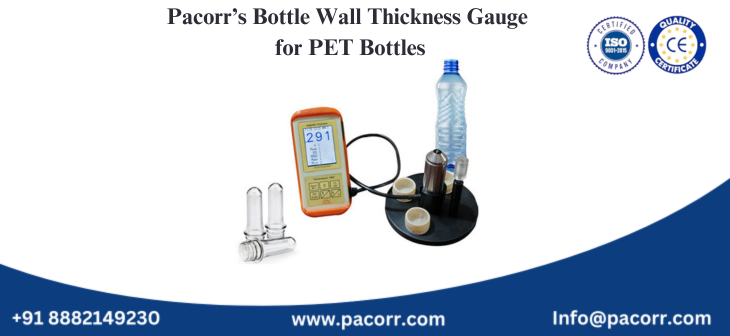

Pacorr’s Bottle Wall Thickness Gauge for PET bottles is a high-precision testing instrument engineered to meet the evolving demands of modern packaging industries. In a market where bottle durability, uniformity, and material efficiency define quality, this advanced device ensures accurate, non-destructive wall thickness measurement for PET containers. By offering real-time data on material distribution, the gauge enables manufacturers to maintain consistency, prevent defects, and comply with international quality standards all while optimizing production efficiency and sustainability.

Why Wall Thickness Matters in PET Bottle Manufacturing

PET bottles are widely used across industries from beverages and personal care to pharmaceuticals and household products. Their success hinges on lightweight design, clarity, and most importantly, structural strength. A minor inconsistency in wall thickness can compromise the bottle’s ability to withstand internal pressure, leading to deformation, leakage, or even breakage during transportation or storage.

By using Pacorr’s wall thickness gauge, manufacturers gain real-time insights into material distribution across the bottle, ensuring that every container meets performance and quality standards.

What Is a Bottle Wall Thickness Gauge?

The Bottle Wall Thickness Gauge is a non-destructive testing device that measures the thickness of PET bottle walls at various points using either ultrasonic or laser-based technology. This ensures the bottle maintains uniformity throughout its body from base to shoulder without physically damaging the sample.

Non-Destructive, High-Precision Testing

Unlike traditional micrometer-based methods, Pacorr’s gauge does not require cutting or altering the bottle. This allows manufacturers to maintain sample integrity while capturing high-accuracy readings at multiple critical points. The result? Faster testing, less waste, and more reliable data.

How the Technology Works

At the heart of the system lies a high-resolution sensor capable of detecting even the slightest deviations in wall thickness. As the bottle is scanned, the sensor captures real-time data and transfers it to an intuitive digital interface. Engineers can view graphical analytics, compare readings, and make immediate adjustments to production parameters if needed.

This process allows for:

- Immediate detection of inconsistencies

- Analysis across different zones of the bottle

- Data-driven decisions in production environments

Whether dealing with carbonated beverages or pharmaceutical liquids, the gauge adapts effortlessly to different container sizes and shapes.

Designed for Compliance with Global Standards

To support international manufacturing needs, Pacorr’s thickness gauge aligns with ASTM D1998, ISO 23529, and ISO 527 standards. These global benchmarks govern plastic testing and ensure the device is ready for use in regulated industries like food packaging, pharmaceuticals, and cosmetics.

Complying with these standards allows manufacturers to confidently export their products worldwide while maintaining consistent quality and safety.

Supporting Sustainable Packaging Goals

The shift towards lightweight, eco-friendly packaging is undeniable. As manufacturers reduce plastic use to lower costs and meet sustainability targets, maintaining structural strength becomes more challenging. Thinner walls can easily lead to deformation or breakage if not properly monitored.

That’s where Pacorr’s Bottle Wall Thickness Gauge proves indispensable. It helps manufacturers optimize material use without compromising performance, enabling a balance between environmental responsibility and practical durability.

Applications Across Industries

Pacorr’s gauge finds vital applications in multiple stages of the packaging lifecycle:

In Preform Production

Identifying material inconsistencies in preforms helps avoid costly errors downstream. By testing before blow molding, manufacturers reduce scrap, improve yield, and maintain consistency.

In Blow Molding Operations

After molding, the wall thickness gauge provides assurance that the final bottle meets required dimensions and tolerances key for packaging carbonated drinks or pressurized liquids.

In Filling Plants and QA Labs

At the final stage, the instrument ensures only bottles that pass structural integrity tests reach the consumer. It acts as the last checkpoint in a rigorous quality assurance system.

In R&D and Innovation Labs

For teams developing new designs or PET blends, this tool provides valuable feedback on how changes affect wall distribution. Engineers can iterate mold designs and test variables quickly and efficiently.

Seamless Integration into Production Lines

The system’s compact design and easy-to-operate interface make it suitable for both lab environments and full-scale industrial use. Minimal operator training is required, ensuring a smooth onboarding experience.

Additionally, Pacorr offers modular versions that can integrate with automated inspection lines. This allows manufacturers to receive real-time feedback and implement corrective actions during production an essential feature for Industry 4.0-enabled factories.

Enhancing Hygiene and Repeatability

Especially in the food and pharmaceutical sectors, hygiene is non-negotiable. Thanks to its non-contact nature, Pacorr’s thickness gauge eliminates contamination risks while providing repeatable results across thousands of test cycles.

Repeatability ensures consistency not just from one bottle to the next, but across entire batches and shifts, reducing variability and boosting customer trust.

Real-World ROI: More Than Just a Testing Tool

Let’s face it testing instruments are often seen as cost centers. But Pacorr’s Bottle Wall Thickness Gauge flips that idea on its head. By identifying weak points early, manufacturers prevent:

- Product recalls

- Customer complaints

- Wastage due to overfilling or bursting

Over time, this translates to lower operating costs, higher customer satisfaction, and a stronger brand reputation.

Stay Audit-Ready and Market-Compliant

In many export-focused markets, compliance audits are the norm. Whether you're preparing for a regulatory inspection or aiming for ISO certification, having a trusted wall thickness gauge in place makes the process smoother.

It not only helps demonstrate your commitment to quality but also ensures documentation and data logs are available for external review.

Why Choose Pacorr?

I’ve built Pacorr’s solutions with the evolving needs of manufacturers in mind. Our Bottle Wall Thickness Gauge stands out due to:

- Precision engineering

- Compliance with international testing standards

- User-friendly interface

- Adaptability to multiple bottle shapes and sizes

- Outstanding after-sales support

I understand that every production line is unique. That’s why we provide customized setup consultations, training, and ongoing technical assistance to make sure the instrument delivers consistent value from day one.

The Future of PET Bottle Testing Is Here

As the packaging industry pushes the boundaries of innovation, quality control must evolve alongside. With Pacorr’s Bottle Wall Thickness Gauge for PET bottles, you get more than just a device you get a partner in performance, compliance, and sustainability.

Whether you’re scaling production, launching a new line, or tightening your quality processes, investing in accurate wall thickness measurement is a strategic decision. One that ensures every bottle that leaves your facility reflects the strength, reliability, and precision your brand stands for.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.