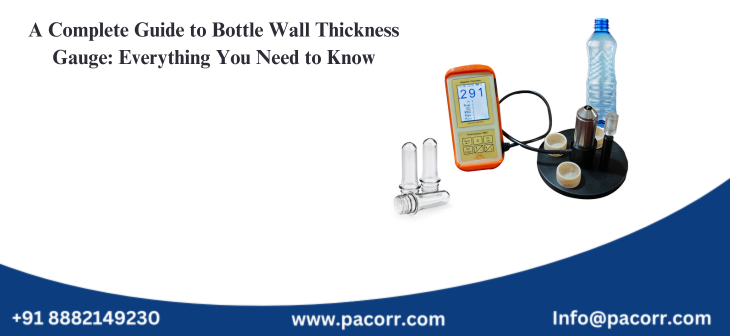

A bottle wall thickness gauge is a precision tool that plays an essential role in various industries, helping to ensure product quality, structural reliability, and compliance with safety standards. It is a critical device for measuring the thickness of walls in materials such as plastics, glass, metals, and coatings without damaging the object being tested. From assessing the quality of pipes to testing bottles and coatings, a wall thickness gauge helps maintain accuracy and consistency.

This guide offers an in-depth understanding of wall thickness gauges, the types available, and their specific applications, empowering one to make an informed choice.

What is a Wall Thickness Gauge?

A wall thickness gauge is a device used to measure the thickness of a material's wall with high precision. It is commonly used in industries where maintaining consistent material thickness is essential to ensure the durability and functionality of products. It works as a non-destructive testing tool, which means it provides accurate measurements without damaging or altering the material.

A wall thickness gauge helps in identifying flaws like material thinning, uneven distribution, or defects that can affect the product’s performance and longevity. Its applications are critical in fields such as manufacturing, packaging, oil and gas, construction, and more.

Why is a Wall Thickness Gauge Important?

A wall thickness gauge serves as a reliable tool for maintaining safety, improving efficiency, and achieving cost-effectiveness. It fulfills the following key purposes:

- Ensuring Safety: It helps detect thinning or damaged walls in pipes, tanks, or containers, reducing the risk of structural failure.

- Maintaining Quality Standards: It ensures uniform thickness in products like PET bottles, glass containers, and coatings, adhering to industry regulations.

- Reducing Costs: It detects issues early, minimizing material waste and preventing expensive repairs or rejections during manufacturing.

- Non-Destructive Testing: It enables one to test materials without damaging them, making it an ideal tool for delicate or finished products.

Types of Wall Thickness Gauges

1. Ultrasonic Wall Thickness Gauge

An ultrasonic wall thickness gauge is a versatile tool that uses sound waves to measure thickness. It works by sending ultrasonic waves through the material and calculating the thickness based on the time it takes for the sound to reflect back.

Features of an Ultrasonic Wall Thickness Gauge:

- Provides accurate measurements for both metallic and non-metallic materials.

- Works effectively on curved, flat, or irregular surfaces.

- Detects corrosion, erosion, and thinning in walls.

Applications:

- Measuring the thickness of industrial pipes and tanks.

- Inspecting ship hulls and pressure vessels.

- Ensuring structural integrity in aerospace components.

2. Digital Wall Thickness Gauge

A digital wall thickness gauge offers precision and ease of use, with readings displayed on a digital screen. It is user-friendly and often equipped with advanced features like data storage and export functionality.

Features of a Digital Wall Thickness Gauge:

- Provides highly accurate and real-time measurements.

- Includes a clear digital display for easy readability.

- Offers portability for use in industrial or laboratory settings.

Applications:

- Inspecting PET bottles during production.

- Measuring materials in laboratories for quality assurance.

- Conducting on-site testing in industrial environments.

3. Magnetic Wall Thickness Gauge

A magnetic wall thickness gauge measures the thickness of coatings or non-metallic layers on metallic substrates using magnetic induction. This tool is particularly suitable for coatings on steel and other ferromagnetic materials.

Features of a Magnetic Wall Thickness Gauge:

- Non-destructive and effective for coatings and layers.

- Compatible with curved and flat surfaces.

- Compact and portable for field inspections.

Applications:

- Measuring anti-corrosion coatings on pipelines.

- Testing paint or protective coatings in the automotive industry.

- Assessing metallic components in construction and manufacturing.

Applications of Wall Thickness Gauge for Bottles

Measuring PET Bottles

A PET bottle wall thickness gauge ensures that the walls of plastic bottles used for beverages, cosmetics, and pharmaceuticals are consistent and strong. Uneven wall thickness can compromise the bottle’s durability and safety.

Measuring Glass Bottles

A glass bottle wall thickness gauge provides precision measurements for glass bottles to prevent breakage and ensure their structural integrity. These measurements are especially important in high-pressure environments, such as carbonated beverage packaging.

How to Use a Bottle Wall Thickness Gauge

- Secure the bottle on a testing platform.

- Place the gauge’s sensor on the surface to be tested.

- Record the thickness at various points on the bottle for consistency. Using a bottle wall thickness gauge ensures that the material distribution is even, minimizing product defects and improving performance.

Applications of Wall Thickness Gauge for Pipes

A wall thickness gauge for pipes is essential in industries like oil and gas, chemical processing, and construction. It measures the thickness of pipe walls to detect corrosion or wear that could lead to leaks or structural failure.

Best Tools for Pipes:

- An ultrasonic wall thickness gauge detects internal and external thinning.

- A magnetic induction gauge evaluates coatings on pipe surfaces.

- Regular inspections with these tools extend the life of pipelines and ensure compliance with safety regulations.

Best Practices for Using a Wall Thickness Gauge

To achieve accurate and reliable results, one should follow these best practices:

- Calibrate Before Use: Regular calibration ensures the device provides precise readings.

- Clean the Surface: Remove debris, oil, or dust from the material before testing.

- Take Multiple Measurements: Measure at different points for a comprehensive understanding of material thickness.

- Read Instructions: Familiarize oneself with the gauge’s manual for proper usage.

- Store Safely: Keep the gauge in a dry, protected environment to maintain its functionality.

How to Choose the Right Wall Thickness Gauge

When selecting a wall thickness gauge, it is important to consider:

- Material Type: Ensure the gauge is suitable for the material being tested (metal, plastic, glass, etc.).

- Accuracy Requirements: Choose a gauge that meets the precision standards for the specific application.

- Application Environment: Select a device designed for the conditions it will face, such as high temperatures or corrosive environments.

- Portability: For fieldwork, a compact and lightweight gauge is preferable.

- Ease of Use: A user-friendly design with digital displays and data storage capabilities simplifies the process.

A bottle wall thickness gauge is a versatile and essential tool for industries where precision, quality, and safety are top priorities. From ultrasonic and digital devices to magnetic gauges, each type is designed to meet specific measurement needs. Whether testing pipes, bottles, or coatings, a wall thickness gauge helps ensure compliance, reduce costs, and maintain product standards.

By choosing the right wall thickness gauge and following best practices, one can optimize production processes, enhance product reliability, and achieve long-term savings. Pacorr offers a wide range of wall thickness gauges and precision testing instruments designed for durability and accuracy. With Pacorr’s solutions, one can confidently address any measurement challenge while ensuring high-quality standards.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.