Woven Sack Raffia & Tapes Testing Instruments

Woven Sack Raffia & Tapes Testing Instruments manufacturers and suppliers make sure that they provide the best accuracy testing instruments to the manufacturers of woven sacks raffia and tapes so that they could be used for ensuring better quality control of the products. PP Woven Sacks are commonly produced and printed according to the Customers' requests/needs. The end clients receive various types of Color Combinations and Designs in the Printing of these Sacks to pass on the massage(s), characteristic(s), amount and quality related subtleties and taking care of directions and so forth

The Process of assembling PP Woven Sacks includes following four stages:

1. Tape plant

2. Extrusion

3. Weaving

4. Finishing and Stitching

Tape plant

Expulsion Tape Stretching Plant have been created for delivering PP/HDPE tapes for some applications, for example, Woven Sacks/Knitted Bags/Raffia tapes, FIBC , Jumbo Bags , Carpet Backing, Trapanlins , Wrapping textures and numerous different applications.

Expulsion/overlay

The way toward assembling PP woven sacks includes blending crude materials beginning with PP pellets and different added substances, expelling the crude materials into a yarn PP pitch is warmed with antenna of CaCo3 and pigment, softened and expelled as a level film. It is then cut into tape yarn by the cutting unit and stretched and toughened. Next, a take-up winder winds the warmth situated tape yarn onto a bobbin.

The Raw Material (PP and Filler) in the Granules structure is taken care of to a Raffia Tape Manufacturing Plant to acquire the Raffia Tapes of PP. The Raw Material Mix is set up in a Tray neighboring the Feed Hopper. The readied Mix is sucked in to the Hopper by Vacuum. The Raw Material Mix is brought to the Extruder of the Plant; where the equivalent is dissolve by applying controlled External Heat on the Barrel. The Molten Mass is constrained out through a Die Head into a Cooling Tank, as Sheet/Film. The cooled and set Sheet/Film is gone through the Knifes to get Raffia Tapes of higher Denier (a Unit by which the fineness of a Yarn is estimated). High Density Polyethylene(HDPE) or Polypropylene(PP) granules are first changed over in to 2.5 mm wide tapes by Extrusion measure. The Raffia Tapes got from the Plant are stretched and toughened. These are then injury on Cheese Pipes with the assistance of the Sets of Winders.

Weaving

Weaving the yarn into a texture in a cycle like the weaving of Weaving textiles . These level tapes are then woven into roundabout texture by Circular weaving machine. In this way woven round texture is then sliced in to required measurement . String from the bobbin in the round loom's creel stand is woven into cylindrical material The Weaving of Raffia Tapes into Cloths is completed in Circular Looms, which produce Circular Cloth of wanted Width. The way toward Weaving is Automatic and Continuous in nature. Quantities of Circular Looms are introduced in order to coordinate the Effective Output of the Raffia Tape fabricating Plant. The Cloth created by each Loom is ceaselessly twisted on Rotating Pipes.

Completing and Stitching

The Rolls of Woven Cloth are done to the Finishing and Stitching Section of the Unit. The Cloth is cut into wanted size and the printed. Subsequent to printing the cut pieces are sent for sewing. Preceding the sewing of the Cloth, a valve is made in one corner of the cut piece, according to the Customers particular. The Woven Sacks went through the Quality Control Test are packaged in 500 or 1000 Nos. also, pushed on a Bailing Press. The squeezed Woven Sacks are wrapped, packaged, stuffed and dispatched.

The Quality Control looks at are conveyed at every single means to maintain a strategic distance from dismissals. The boundaries relating to the Weight, Denier, Bursting Strength and so on are carefully clung to.

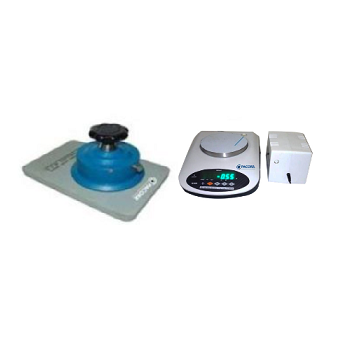

Pacorr is a manufacturer and supplier of high precision Woven Sack Raffia & Tapes Testing Instruments that are used for ensuring the best quality of the sacks and tapes that are manufactured in industries. The instruments are meant to provide the most accurate testing data as they are designed by following all the international testing standards such as ASTM and ISO.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.