Surface Coating Testing Instruments

Surface coatings testing instruments manufacturers and suppliers have a wide range of testing devices to offer to the manufacturers and users of surface coating materials that can be used for ensuring better quality of the products by conducting precise testing procedures on the products as well as the materials.Surface coating, is any combination of film-framing materials in addition to pigments, solvents, and different added substances, which, when applied to a surface and relieved or dried, yields a slender film that is utilitarian and frequently ornamental. Surface coatings incorporate paints, drying oils and stains, engineered clear coatings, and different items whose essential capacity is to shield the outside of an article from the climate. These items can likewise improve the stylish allure of an article by complementing its surface highlights or even by hiding them from sight.

Most surface coatings utilized in industry and by purchasers depend on manufactured polymers—that is, mechanically created substances made out of amazingly enormous, regularly interconnected atoms that structure extreme, flexible, glue films when applied to surfaces. The other part materials of surface coatings are pigments, which give tone, obscurity, sparkle, and different properties; solvents or transporter fluids, which give a fluid medium to applying the film-shaping fixings; and added substances, which give various exceptional properties. This article audits the creation and film-framing properties of polymer-based surface coatings, starting with the polymer fixings and proceeding through the pigments, fluids, and added substances. The accentuation is on paints (by a wide margin the most well-known sort of coating), however periodic reference is made to different kinds of coatings, for example, drying oils and stains.

Polymers for Surface Coatings

Polymer-based surface coatings can be viewed as two-stage composite materials comprising of pigment particles and different added substances scattered in a ceaseless framework of polymer. Polymers give the coating film its ability to hold fast to the substrate, the vast majority of its synthetic opposition, and adaptability. Moreover, the congruity of the film, quite a bit of its strength within the sight of ecological anxieties, its sparkle properties, a large portion of its mechanical and warm properties, and the vast majority of any compound reactivity that the film will display are subject to polymers too.

The key properties of the coating polymer are atomic weight, sub-atomic weight circulation, glass progress temperature (Tg), and solvency. Additionally significant are the responsive sub-atomic gatherings making up the polymer and the energy and system by which the polymer is shaped—that is, regardless of whether it is framed by step-development polymerization or chain-development polymerization. Another key property of the polymer is its structure. Polymers can have straight, fanned, or network designs. The last sort of structure, comprising of polymer chains reinforced covalently at a few destinations to frame a three-dimensionally cross-connected organization, is frequently shaped in the coating film during its relieving.

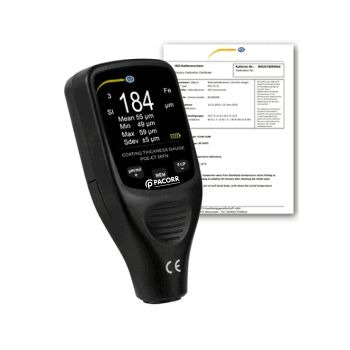

Pacorr offers the most exclusive range of highly precise surface coatings testing instruments that can be used by the manufacturers to ensure the best quality of the products that are delivered to the customers. The instruments are designed to provide the most accurate testing data to the users along with great ease of use so that the best quality of coating products could be assured.

.jpg)

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)