Plastic Rope Testing Instruments

Plastic Rope Testing Instruments manufacturers and supplier always offer the most profound range of highly precise devices that are used for testing the plastic ropes in the industries. The plastic ropes have a significant role in industries and hence must be tested with the help of best precision Plastic rope testing equipment for better quality assurance. There is a variety of ropes used in industries as well as for other applications. Polypropylene rope is most usually utilized here in the States as "ski rope." It is economical, light weight, solid and it skims. However, the polymer structure of polypropylene (and most different polyolefins like polyethylene, and so on) isn't impervious to bright. At the point when presented to daylight, it rapidly debases from the bright radiation. The outcome is extensive debilitating of the rope alongside surface oxidation. The loss of elasticity is normally a terrible thing for a guying application. The surface oxidation is of not much worry here, but rather when utilized as an encasing, (for example, on the finishes of a wire dipole), the oxidized surface becomes vulnerable to wet conditions permitting surface tainting to follow.

To slow the corruption of polypropylene rope, or any plastic besides, enemies of oxidants and bright inhibitors might be included. These expansion the life of the rope fairly, however they don't offer ever-enduring assurance. Certain shadings offer better bright assurance as well. I am certain that the vast majority know about the way that natural colors and pigments blur. Red is presumably the most exceedingly terrible wrongdoer, trailed by yellow. Splendid white and dark by and large hold up the best. In polypropylene rope, the dark will by and large show improvement over the white. Since the polypropylene is normally clear, it takes minimal white pigment (for the most part titanium dioxide) to make it white. Dark is economically gotten by adding carbon dark to the polymer dissolve.

Polyester ropes have extremely low stretch creation them astounding for guying applications. They are superb in both compound and bright obstruction. The polyester materials have a fascinating property that makes them particularly bright safe. These materials fluoresce upon presentation to bright light; they retain bright radiation and re-transmit it as light at a more extended frequency. There are other strength ropes accessible, for example, those produced using polyaramides (Kevlar and Nomex) and polyimides. The Kevlar ropes are amazingly solid, yet they require unique abandoning and covering to keep away from scraped spot issues; their scraped area obstruction is very poor.

Due to such an extensive use of plastic ropes in various fields, the manufacturers must ensure their best quality by testing the ropes with high precision plastic ropes testing instruments that allow the manufacturers to deeply analyze the rope properties and ensure higher quality.

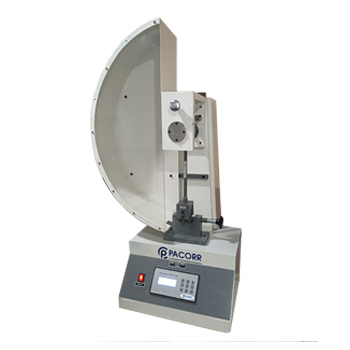

Pacorr is one of the most reliable provider of plastic ropes testing instruments that are highly precise and very useful for the manufacturers of plastic ropes. The instruments help in deep understanding of the behavior and properties of plastic ropes and ensure better quality assurance. The instruments are made from high grade elements and are capable of accurate performance in industrial working conditions.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)