Plastic Injection Molding Testing Instruments

Plastic Injection Molding Testing Instruments manufacturers and suppliers offer wide array of testing instruments that are used in the injection molding industry for testing the products that are manufactured with the help of injection molding process. The injection molding products are used in a variety of applications in industries hence the manufacturers must ensure best quality of the products by testing their quality with precise Plastic Injection Molding Testing instruments.

What is injection molding?

Plastic injection molding is the way toward softening plastic pellets (thermosetting/thermoplastic polymers) that once pliable enough, are infused at pressure into a hill cavity, which fills and sets to create the eventual outcome.

How Does Plastic Injection Molding Work?

The thermoplastic injection molding is a standard cycle including an aluminum shape. Aluminum moves heat considerably more proficiently than steel, so doesn't need cooling channels - which implies the time we save money on cooling can be applied to checking fill pressure, restorative concerns and creating a quality part.

Sap pellets are stacked into a barrel where they will in the end be softened, compacted, and infused into the form's sprinter framework. Hot tar is shot into the form depression through the doors and the part is shaped. Ejector pins encourage expulsion of the part from the shape where it falls into a stacking container. At the point when the run is finished, parts (or the underlying example run) are boxed and dispatched presently. Solicitation your Free Design Cube which shows surface completions and good and bad wraps up.

Injection molding machine is isolated into 2 units for example a clasping unit and an injection unit. The elements of the bracing unit are opening and shutting a bite the dust, and the launch of items. There are 2 kinds of clasping techniques, to be specific the switch type appeared in the figure beneath and the straight-water driven sort in which a shape is straightforwardly opened and shut with a pressure driven chamber.

The elements of the injection unit are to liquefy plastic by warmth and afterward to infuse liquid plastic into a form. The screw is pivoted to dissolve plastic acquainted from the container and with amass liquid plastic before the screw ( to be called metering ) . After the necessary measure of liquid plastic is gathered, injection measure is gazed. While liquid plastic is streaming in a form, the machine controls the moving velocity of the screw, or injection speed. Then again, it controls stay pressure after liquid plastic rounds out pits. The situation of progress from speed control to pressure control is set at where either screw position or injection pressure arrives at a specific fixed worth.

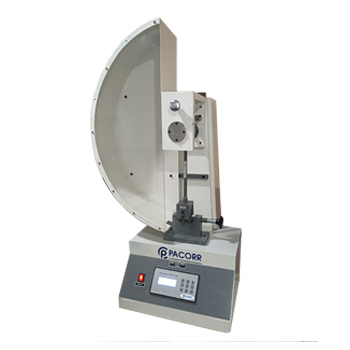

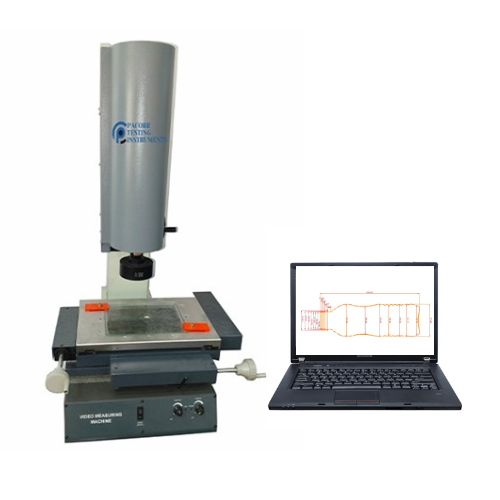

Pacorr is a manufacturer supplier and exporter of highly precise testing instruments that are being used by the manufacturers of injection molding plastic products. The instruments offered by Pacorr involve highly advanced technologies that ensure better precision of the testing data. Also the instruments comply to the international quality standards and hence increasing the credibility of the testing data in the international markets.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)