Paint Testing Instruments

Paint Testing Instruments manufacturers and suppliers offer a wide variety of high precision testing instruments that have been used in the paint industries for ensuring and enhancing the high quality of products. Paints are extensively used in industries as well as domestic fronts. In order to prevent defects in post-production or, at least, to determine the causes defects and failures that may occur on the products, It is important to verify the characteristics of the coatings with regard to thickness, hardness, adhesion to the substrate, color, resistance to corrosion and to climatic agents, bearing in mind the scope of use.

CHEMICAL ANALYSIS

For chemical analysis of the surface protection layers, depending on the type of coating, several analytical techniques may be used:

PHYSICAL AND MECHANICAL TESTS

To verify the characteristic parameters of the coatings concerning the properties required to them, several physical-mechanical tests may be conducted in order to obtain specific information such as the thickness of the coating and the verification of the treatments it has sustained (conversions , ...), brightness, color, hardness, adhesion or resistance to breakage due to violent deformation of the support.

CONDITIONING

Tests can be conducted to determine the behavior of paints and other types of coatings to prolonged exposure to conditions of temperature/humidity defined in accordance with the requirements of the coating or product specifications. These tests provide an indication of the likely performance that can be achieved under severe conditions of exposure when, for example, sudden temperature changes or prolonged exposure to high temperatures occur.

The procedures may show damage to the coating (blisters, spots, softening, wrinkling, detachment and embrittlement) and deterioration of the support.

RESISTANCE TO CORROSION

On paints and coatings may be conducted tests of resistance to corrosion in salt spray (NSS), acetic acid salt spray (AASS) and copper acetic acid salt spray (CASS) in accordance with ASTM B117 and ISO 9227 on metals and alloys, metallic coatings (anodic and cathodic), conversion coatings, anodic oxidation coatings and organic coatings on metal material.

AGING

In order to evaluate the behavior of paints and coatings in particular atmospheric or exposure conditions (humidity, temperature, sunlight, UV exposure) may be conducted accelerated aging tests in order to reproduce in the laboratory situations particularly severe. As a result of the aging test, a visual evaluation of the result is made and / or may be conducted further investigations on the specific characteristics requested to the coating under examination.

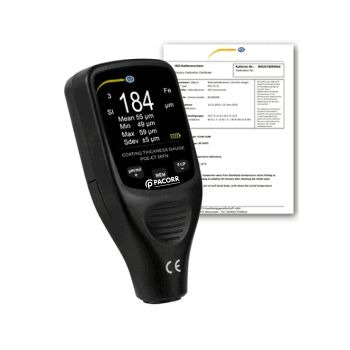

Pacorr is a reliable provider of highly precise paint testing instruments that have been used by the paint industry to ensure the best quality of products delivered to the clients. The instruments offered by Pacorr are specially designed keeping in focus the testing requirements of the paint industry and hence are capable of delivering accurate testing data to the users. The instruments are made for a longer service life by using the best grade materials. It also allows them to work in extreme conditions without compromising with the accuracy.

.jpg)

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)