Masterbatch Testing Instruments

Masterbatch Testing Instruments manufacturers and suppliers offer highly accurate testing machines that are used in industries that are meant to providing highly precise testing data about the quality of the master batches produced in a manufacturing facility.

Masterbatch (MB) is a strong added substance for plastic utilized for shading plastics (shading masterbatch) or giving different properties to plastics (added substance masterbatch). A fluid dose structure is called fluid tone. Masterbatch is a concentrated combination of shades as well as added substances embodied during a warmth cycle into a transporter pitch which is then cooled and cut into a granular shape. Masterbatch permits the processor to shading crude polymer financially during the plastics fabricating measure.

The options in contrast to utilizing masterbatches are purchasing a completely aggravated material (which might be more costly and less open to for example shading fluctuation of the item), or exacerbating from crude materials on location (which is inclined to issues with accomplishing full scattering of the colorants and added substances, and inclined to getting ready more material than what is utilized for the creation run). In examination with unadulterated shades, masterbatches require more extra room and their lead times are longer. Another drawback is extra presentation of warmth ("heat history") to both the transporter and the added substance; this might be significant for example for imperceptibly thermally stable pigments.

As masterbatches are as of now premixed creations, their utilization eases the issues with the added substance or colorant bunching or inadequate scattering. This is the reason the manufacturers must utilize Masterbatch testing instruments to guarantee that best quality items is given to the customers. The convergence of the added substance in the masterbatch is a lot higher than in the end-use polymer, yet the added substance is as of now appropriately scattered in the host gum. In a manner their utilization is like employments of ferroalloys for adding alloying components to prepare.

The utilization of masterbatches permits the manufacturing plant to keep supply of less evaluations of the polymer, and to purchase less expensive normal polymer in mass.

The masterbatches can be decently profoundly focused (in examination with the objective creation), with high "let-down proportions"; for example one 25 kg pack can be utilized for a huge load of common polymer. The generally weaken nature of masterbatches (in examination with the crude added substances) permits higher exactness in dosing modest quantities of costly parts. The transporter material of the masterbatch can be founded on a wax or on a particular polymer, indistinguishable or viable with the common polymer utilized (polymer-explicit). For example EVA or LDPE can be utilized as transporters for polyolefins and nylon, polystyrene can be utilized for ABS, SAN, and once in a while polycarbonates.

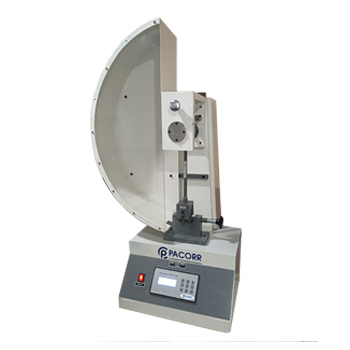

Pacorr offers highly advanced and precise Masterbatch testing instruments that are being used by industrial manufacturers in testing the quality of the masterbatches that are being manufactured by them. The devices that are provided by the manufacturers are easy to use due to their ergonomic designs and the testing data obtained from them are internationally acceptable as they follow the standards such as ASTM and ISO.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)