Leather Testing Instruments

Leather Testing Instruments manufacturers and suppliers ensure that they provide the highest possible quality testing devices to the leather industries. These instruments help the manufacturers in ensuring the best quality of the products delivered in the market.

Leather is a material cherished by numerous individuals for its adaptability and toughness. It is produced using tanning creature skins or stows away and a wide range of creatures are utilized to make leather. Leather has four fundamental grains or characteristics; those are full-grain leather, top-grain leather, certifiable leather, and remedied grain leather.

Full-grain leather is described by its sumptuous, smooth surface and it has hardly any, blemishes. It is the most mainstream kind of leather. It has not been snuffed, sanded, or polished to eliminate any normal imprints or blemishes from its surface. Its strands are steady and sturdy on the grounds that the grain has not been eliminated. There is less dampness in the leather from any drawn out contact as the grain has an attribute of relaxing. This sort of leather doesn't destroy without any problem. Rather, it builds up a patina, which is a slender layer that shields the leather from harm from wearing or consuming; it additionally gives the leather a stylish look. It is utilized in making excellent footwear and furniture.

Top-grain leather has the second-most noteworthy leather quality of the top of the line classification of leather items. It is more flexible and more slender as its layer is isolated away. Its surface is sanded, and a completion cover is added to cause it less breathable with a plastic to feel and this causes it to appear to be cooler. Additionally, it creates pinna that shields it from harm and erosion making it last more. It has better stain obstruction and is more affordable than full-grain leather. Numerous individuals favor purchasing this kind of leather as it is strong and promptly accessible.

Certifiable leather is produced using genuine foam. The quality of leather can be assured with the help of laboratory leather testing instruments. In a class of genuine leather items, certifiable leather items are the most reduced in quality. These items are produced using the extra of leather after the very good quality items are made. The items made from it don't look or feel as satisfying contrasted with those produced using top notch leather. In like manner, items produced using certifiable leather don't keep going as well before they wear out. Notwithstanding, the vast majority can manage the cost of this kind of leather item as they are generally accessible.

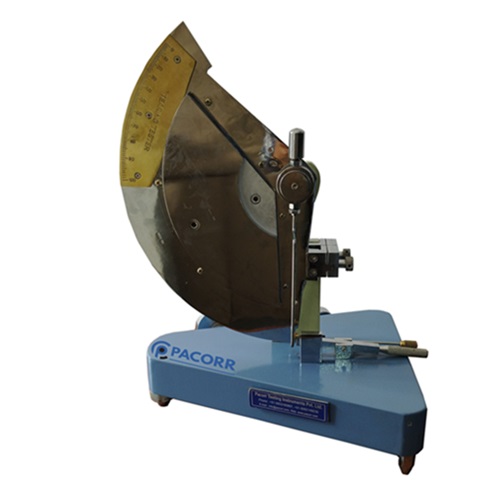

Pacorr offers a wide variety of Leather Testing Instruments that have been used by manufacturers of leather products for enhancing the quality of the products by spotting the quality flaws in the products in the early stages and amend them. The instruments offered by Pacorr are made from very high grade materials and hence the manufacturers can use the instruments in harsh working conditions. The devices follow the standards such as ASTM and ISO and hence are acceptable in the international markets as well.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.