FRP Products Testing Instruments

FRP Products Testing Instruments manufacturers and suppliers are dedicated to provide the plastic industries, the most precise testing devices. These devices are used by the manufacturers for the most of the testing procedures and ensure better quality of the products they delivered to the customers. FRP products are mainly the fiber-reinforced plastic products that are made from composite mix of a polymeric material along with reinforcement of fibers. The fibers that are used in FRP products include glass, basalt, aramid, carbon. Some rarely used fibers for FRP products include wood, asbestos, paper. The polymeric materials that are used in the FRP products include epoxy, vinyl ester, and polyester thermosetting plastic. In some cases the phenol formaldehyde resins are also used for making FRP products.

When the FRP products are formed, there are two different process followed by the manufacturers. The first is the forming of fibrous material and the second is the boding of the fiber with the polymeric resin to form a matrix. The fibers are manufactured in both three dimensional orientation as well as two dimensional orientation. Preforms of the fibers are manufactured before they are bonded with the matrix. The most common methods of manufacturing fibers is though the textile techniques such as weaving, knitting, braiding and stitching.

Once the fibers are forms, the forming process is started using a rigid structure that is used for giving shape to the final components. The fibers are placed in the preforms. The fibers can be placed dry in the molds or they can be placed in the molds with a small amount of resin present with them called a prepreg. The resin is then injected in the mold and then heat or pressure is applied on the mold for the curing of the resin.

The FRP products are mainly used in the applications where there is a demand for lower weight and high precision of measurements. The FRP products provide a high strength value along with definitive tolerances which makes it ideal for many different industrial applications. They can be used for carbon reinforced polymers used ion aircrafts. Engine intake manifolds along with automotive gas and clutch pedals can be made with glass reinforced polymers. The manufacturers of the FRP products must ensure that the products they deliver to the industries are of best quality and are capable of bearing the loads that will be levied on them during usage. If the quality control of the products is neglected it can be lead to lethal accidents. The FRP Products Testing Instruments can be very helpful for the manufacturers in ensuring a high quality of predict that are capable of delivering higher performance without any chances of failure.

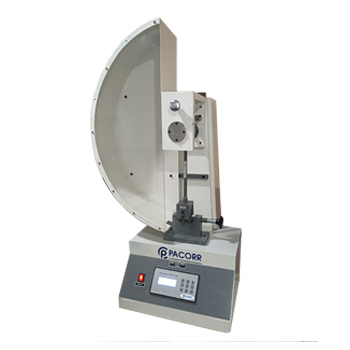

Pacorr offers a wide variety of laboratory FRP Products Testing Instruments that have been used by the manufacturers for ensuring better quality control of the FRP products produced in their facilities. The instruments offered by Pacorr are designed in compliance to the international standards like ASTM which makes them highly precise and accurate and increases the credibility of the testing data obtained from the devices.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)