Coating Testing Instruments

Coating testing instruments manufacturers and suppliers ensure that the quality of testing instruments they provide are of best quality and are able to provide best testing data to the manufacturers of the coating materials. Protective coatings are a basic method to decrease consumption, by restricting the introduction of the metal to a destructive climate. Paint is a typical protective coating, however tar, pitch, bitumen and plastics are additionally utilized. A significant thought for protective coatings is to guarantee the coating is very much clung to the metal, and that it stays unblemished or is routinely fixed/recoated. The quality of coating must be tested thorugh coating testing instruments so that the manufacturers could ensure best quality and protection of the surfaces.

A further type of protective coating is to plate a layer of another metal onto the outside of the metal you wish to secure. One sort of this coating is known as electrifying, where zinc is plated onto iron or steel. On account of electrifying, the zinc goes about as an anode and erodes specially to the iron or steel.

There are four kinds of protective coatings for metal: obstruction, inhibitive, conciliatory, and blend.

Boundary coatings secure metal by forestalling water, oxygen, and electrolyte from interacting with the hidden metal. Inhibitive coatings contain synthetics that ruin consumption. They respond with the cathode, anode, or different parts (oxygen, electrolyte, corrosive). Conciliatory coatings give galvanic assurance. All in all, they erode (penance) rather than the fundamental metal, giving electrons, which switches the erosion cell and changes anodes to cathodes.

On the off chance that UV introduction is a significant concern, or in the event that you are for all time introducing a framework close to salt water or for a very destructive application, stirred steel is solid and amazingly successful. In the electrifying cycle, steel is covered with Zinc to shield it from erosion. Hot plunge arousing gives thick, tough erosion assurance, and it very well may be applied quickly—offsite and under controlled conditions.

Another advantage to utilizing aroused steel is that it is accomplished utilizing normally happening zinc composites. The zinc coating fills in as a conciliatory anode, which consumes rather than the hidden metal. This erosion gives electrons that invert the consumption cell and change anodes to cathodes.

Coatings Quality Testing

Coating measures are known to shield materials and parts from corruption brought about by destructive components. The test for a coating's destructive opposition is frequently done in a salt shower climate. The coating will be exposed to a very destructive climate for a fixed timeframe and afterward be assessed for any signs destructive harm. Taber scraped spot tests are profoundly viewed as one of the speediest, least difficult and financially savvy strategies for social occasion practically identical indications of-wear information from a multiple coatings. Coatings that go through this quality test will be exposed to cyclic grating powers that are made by particular Taber wheels. Estimations will be taken when the test to help create mass-misfortune information.

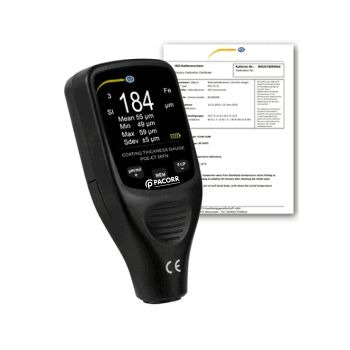

Pacorr offers a wide variety of coating testing instruments that must be used for testing the quality of plating, paint and coatings to ensure that the quality of the products delivered to the clients and industries. The instruments offered here are designed using advanced technologies and are capable of offering the best accuracy test results to the users.

Thanks to Pacorr Testing instruments, we have all the required quality testing instruments that have helped us to ensure the best quality delivered to our clients.

Danish

Fair Exports Pvt. Ltd.

.jpg)